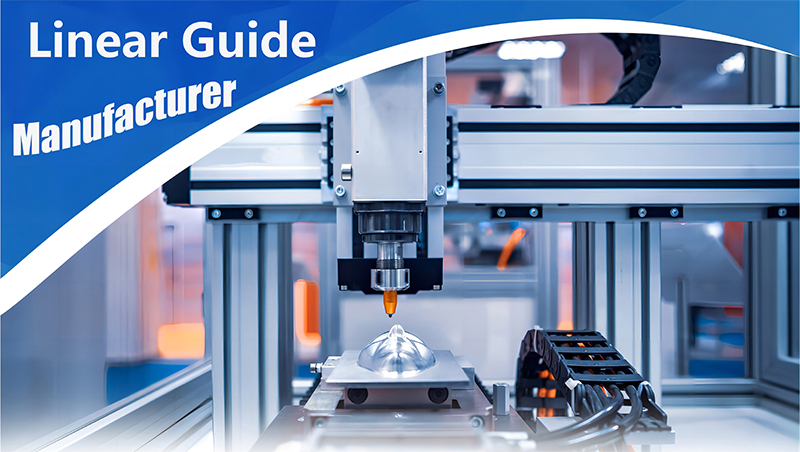

Low Noise CNC Lathe Slide Rail Linear Motion Guide Support Shaft Stainless Steel Linear Guide Rail

In the realm of precision machining, where every micron matters, the choice of linear motion guide systems plays a critical role in determining the quality and accuracy of the final product. Among the array of options available, the Low-Noise CNC Lathe Slide Rail Linear Motion Guide Support Shaft Stainless Steel Linear Guide Rails stand out as a beacon of excellence, offering a host of benefits that elevate machining performance to new heights. Let's explore the features and advantages that make these guide rails indispensable in modern manufacturing.

Unparalleled Precision and Stability

At the core of the Low-Noise CNC Lathe Slide Rail Linear Motion Guide Support Shaft Stainless Steel Linear Guide Rails is their exceptional precision and stability. Constructed from high-quality stainless steel, these guide rails provide a rigid and durable foundation for linear motion, ensuring minimal deflection and vibration during operation.

The incorporation of support shafts further enhances stability, preventing sagging or bending under load. This rigidity translates into superior machining accuracy, allowing for the production of parts with tight tolerances and intricate geometries.

Reduced Noise Levels for Enhanced Working Environment

One of the standout features of these guide rails is their low-noise operation. The advanced design and precision manufacturing techniques employed in their construction minimize friction and vibration, resulting in smooth and silent motion.

In an industrial setting where noise pollution can be a concern, the low-noise characteristics of these guide rails contribute to a quieter and more comfortable working environment. This not only improves the well-being of operators but also enhances overall productivity by reducing distractions and fatigue.

Corrosion Resistance and Longevity

Stainless steel is renowned for its exceptional corrosion resistance, making it an ideal material choice for guide rails operating in demanding environments. Whether subjected to coolant, cutting fluids, or harsh chemicals, these guide rails maintain their integrity and performance over time, ensuring long-term reliability and longevity.

The resistance to corrosion also translates into reduced maintenance requirements, saving time and resources that would otherwise be spent on upkeep and replacement. This makes the Low-Noise CNC Lathe Slide Rail Linear Motion Guide Support Shaft Stainless Steel Linear Guide Rails a cost-effective solution for machining operations seeking to minimize downtime and maximize efficiency.

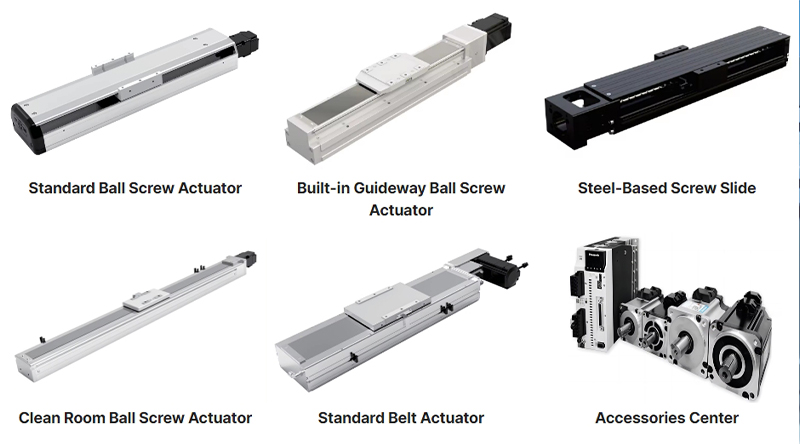

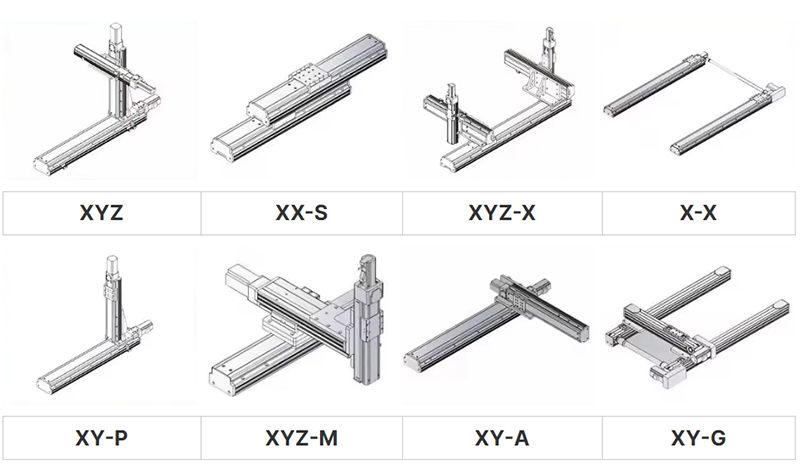

Versatility and Adaptability

Despite their robust construction, these guide rails offer versatility and adaptability to suit a wide range of machining applications. Whether used in CNC lathes, milling machines, grinders, or other precision equipment, they deliver consistent performance and precision across diverse operating conditions.

Moreover, their modular design facilitates easy integration into existing machinery or retrofitting onto older systems, enabling manufacturers to upgrade their equipment without the need for extensive reengineering.

Conclusion

In an era where precision and efficiency are paramount in manufacturing, the choice of linear motion guide systems can make all the difference. The Low-Noise CNC Lathe Slide Rail Linear Motion Guide Support Shaft Stainless Steel Linear Guide Rails embody the pinnacle of engineering excellence, offering unparalleled precision, stability, and reliability.

With their low-noise operation, corrosion resistance, and versatility, these guide rails empower machining operations to achieve new levels of productivity and quality. As the backbone of precision machining, they pave the way for innovation and advancement in industries where excellence is the standard.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.