QFB60 Linear double guide rail step servo screw slide table fully enclosed module

In the ever-evolving landscape of precision engineering and manufacturing, the pursuit of higher accuracy, efficiency, and versatility drives innovation. Enter the Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module – a sophisticated solution designed to meet the demanding requirements of modern industrial applications. Let's delve into the features and benefits that make this technology a game-changer.

Unraveling the Technology

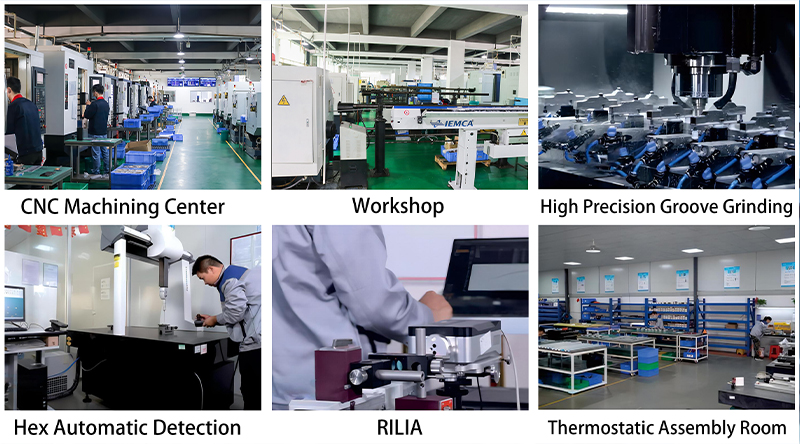

The Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module combines several cutting-edge technologies to deliver unparalleled performance in linear motion control. At its core, this module features a double guide rail system, providing enhanced stability and rigidity during operation. This design minimizes vibration and ensures smooth, precise movement along the linear axis.

Integral to its functionality is the step servo motor, a high-precision motor capable of delivering precise positioning and torque control. Coupled with advanced servo control algorithms, this motor enables the module to achieve exceptional accuracy and repeatability, crucial for applications requiring tight tolerances.

The heart of the system lies in the servo screw mechanism, which translates rotational motion into linear motion with utmost precision. This mechanism, combined with the double guide rail system, forms the foundation of the module's exceptional performance, making it ideal for applications where accuracy is paramount.

Enhanced Performance Through Enclosure

What sets the Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module apart is its fully enclosed design. Enclosing the entire mechanism within a protective housing offers several advantages. Firstly, it provides robust protection against environmental contaminants such as dust, debris, and moisture, safeguarding the internal components and prolonging their lifespan.

Furthermore, the enclosure enhances safety by preventing accidental contact with moving parts, mitigating the risk of injury in industrial settings. Additionally, it reduces noise levels, contributing to a quieter and more comfortable working environment.

Versatility and Adaptability

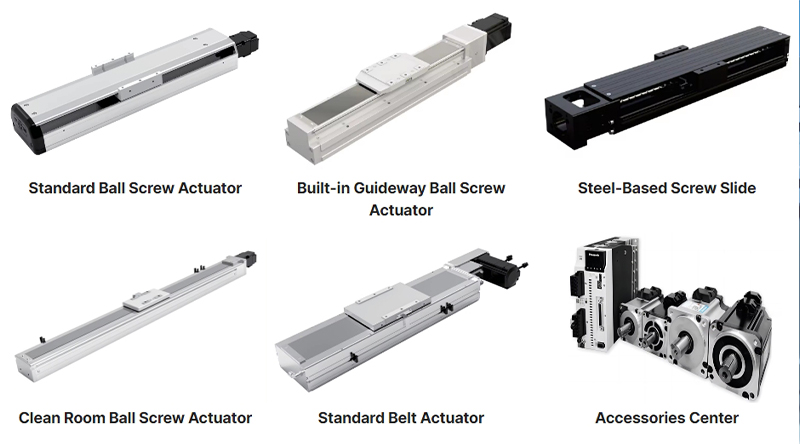

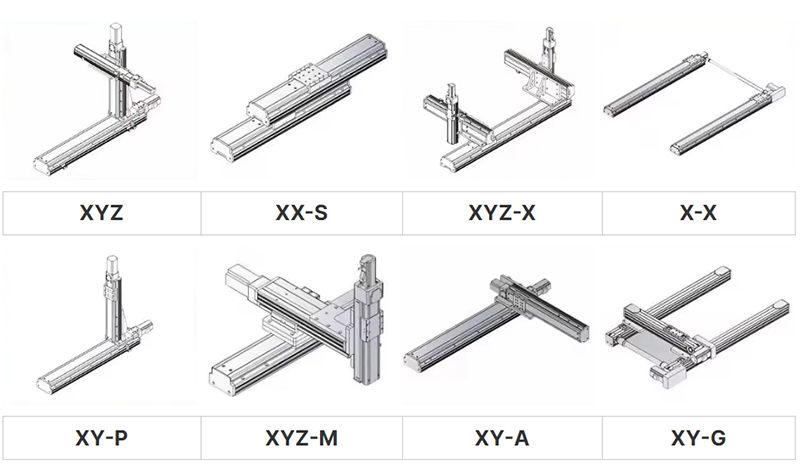

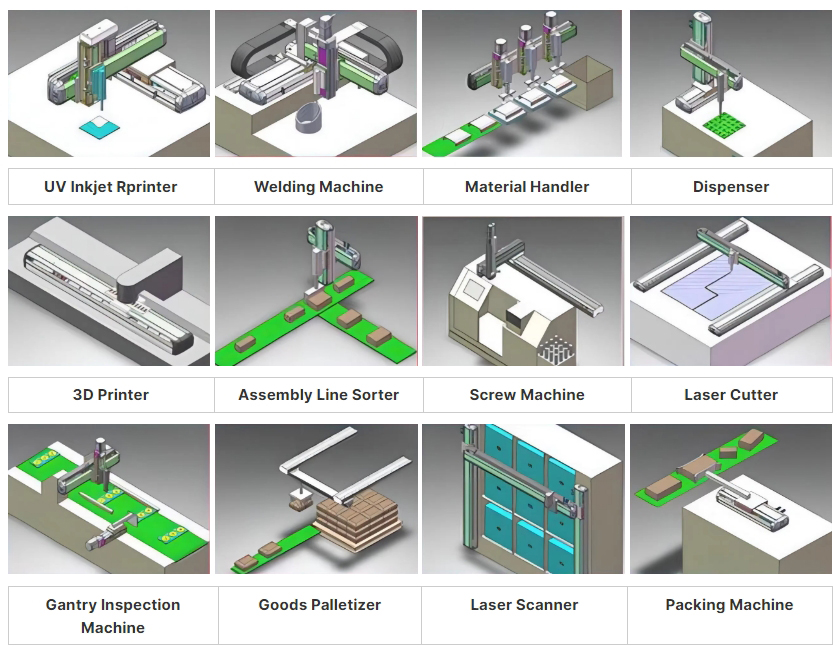

Despite its advanced features, the Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module remains remarkably versatile. Its modular design allows for easy integration into various systems and applications, whether it's in precision machining, automated assembly lines, or laboratory instrumentation.

Moreover, the module's compatibility with a wide range of control interfaces and protocols enables seamless integration into existing automation systems, facilitating interoperability and scalability.

Unlocking New Possibilities

The introduction of the Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module opens up new possibilities for engineers and manufacturers across industries. Its combination of precision, reliability, and adaptability empowers users to tackle even the most demanding tasks with confidence.

Whether it's optimizing production processes, improving product quality, or enhancing research capabilities, this technology represents a significant step forward in the quest for excellence in linear motion control.

Conclusion

In an era defined by relentless technological advancement, the Linear Double Guide Rail Step Servo Screw Slide Table Fully Enclosed Module stands as a testament to the ingenuity and innovation driving the field of precision engineering. With its state-of-the-art design, unmatched performance, and versatility, it promises to redefine the standards of linear motion control, opening doors to new possibilities and propelling industries towards greater heights of efficiency and excellence.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.