Hand screw linear module slide table

In the realm of engineering and manufacturing, precision and flexibility are paramount. Whether it's in the domain of robotics, automation, or intricate machinery, the ability to finely control movement along a linear axis is essential. This is where hand screw linear module slide tables come into play, offering a versatile and precise solution to motion control needs.

Understanding Hand Screw Linear Module Slide Tables

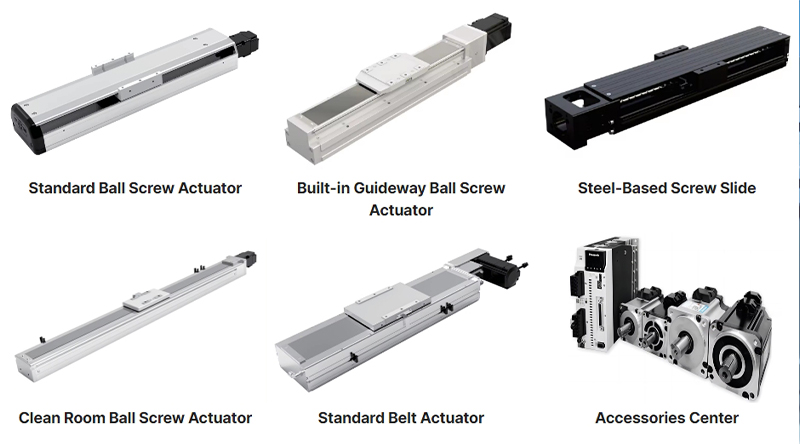

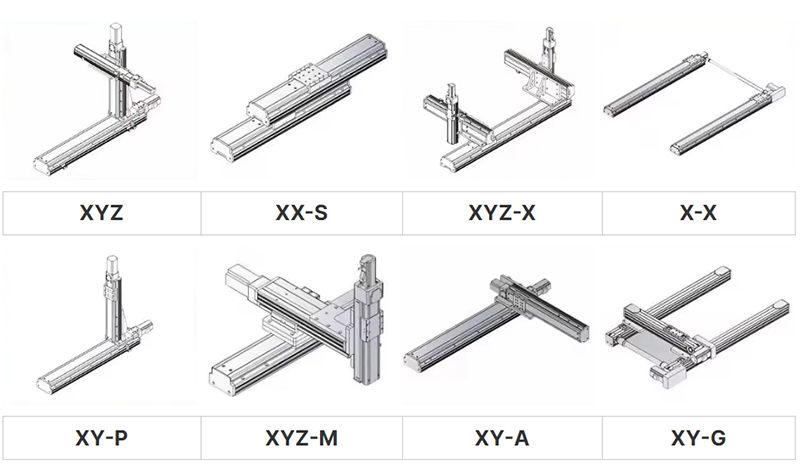

Hand screw linear module slide tables, often referred to simply as slide tables, are mechanical devices designed to facilitate linear motion along a guided path. Unlike traditional linear actuators driven by motors or pneumatic systems, slide tables rely on manual operation through hand-cranked screws. This manual control offers a unique set of advantages in various applications.

Precision at Your Fingertips

One of the standout features of hand screw linear module slide tables is their exceptional precision. By utilizing hand-cranked screws, operators have direct control over the speed and position of the slide table. This granular level of control enables precise adjustments, making it ideal for tasks that require fine-tuning or delicate positioning.

In manufacturing processes where tolerances are tight and accuracy is critical, hand screw slide tables shine. Whether it's in assembly lines, testing equipment, or quality control stations, the ability to precisely position components or tools can significantly enhance productivity and product quality.

Versatility in Application

Another key advantage of hand screw linear module slide tables is their versatility. Unlike motor-driven linear actuators that require electrical power and complex control systems, slide tables can be easily integrated into various setups with minimal infrastructure requirements.

This versatility makes hand screw slide tables suitable for a wide range of applications across different industries. From laboratory instrumentation to woodworking machinery, their simplicity and adaptability offer engineers and designers the flexibility to incorporate them into diverse projects.

Simplifying Complex Tasks

While motorized linear actuators excel in high-speed, repetitive tasks, hand screw slide tables offer a different set of benefits. Their manual operation allows for a more intuitive and hands-on approach to motion control. This can be particularly advantageous in scenarios where real-time adjustments are needed or where automation is not feasible.

For example, in research and development settings, engineers often require the ability to quickly iterate on prototypes or conduct experiments that demand precise adjustments. Hand screw slide tables provide the means to make these adjustments on the fly, empowering researchers to focus on their work without being constrained by the limitations of automated systems.

Conclusion: A Tool for Precision and Control

Hand screw linear module slide tables represent a valuable addition to the toolkit of engineers and manufacturers seeking precision and flexibility in motion control. With their ability to deliver precise positioning, versatility in application, and simplicity in operation, these devices offer a compelling solution for a wide range of tasks.

As technology continues to evolve, it's essential not to overlook the effectiveness of mechanical solutions like hand screw slide tables. While automation undoubtedly has its place, there are instances where manual control remains not only relevant but indispensable. In these situations, hand screw slide tables prove that sometimes, the most effective tool is the one you can operate with your own hands.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.