Tight Tolerance Machining ±0.005mm for Precision Assemblies

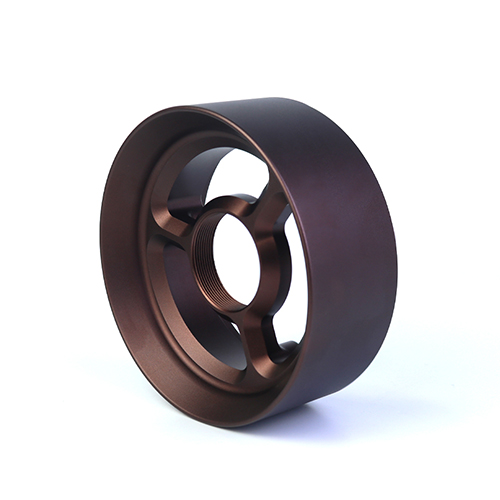

Product Overview

When it comes to high-performance machinery, aerospace components, or medical devices, even a fraction of a millimeter can make or break functionality. That’s where tight tolerance machining (±0.005mm) comes in—the gold standard for industries where precision isn’t just a preference; it’s a necessity.

Tight tolerance machining refers to manufacturing parts with extremely small allowable deviations—often as little as ±0.005mm (5 microns). To put that in perspective, a human hair is about 70 microns thick, meaning these tolerances are 14 times finer than a single strand!

Industries That Demand This Level of Precision

✔ Aerospace – Turbine blades, fuel nozzles, and landing gear must fit perfectly to avoid catastrophic failure.

✔ Medical Devices – Surgical tools, implants, and diagnostic equipment require flawless dimensions.

✔ Automotive (Performance & EV) – High-efficiency engines and battery components rely on exact clearances.

✔ Semiconductor & Electronics – Micro-components need ultra-precise machining to function correctly.

1.Advanced CNC Machines

Modern 5-axis CNC mills and Swiss-style lathes can achieve sub-micron accuracy with repeatability.

2.High-Quality Tooling

● Carbide & Diamond-Coated Cutters – Reduce tool wear for consistent results.

● Laser & CMM (Coordinate Measuring Machines) – Verify dimensions in real-time.

3.Temperature & Vibration Control

● Climate-Controlled Workshops – Prevent thermal expansion from altering dimensions.

● Vibration-Dampened Workstations – Minimize microscopic deviations.

In the world of high-stakes engineering, tight tolerance machining (±0.005mm) is what separates "good enough" from "perfect." Whether it's a jet engine part or a life-saving medical implant, this level of precision ensures reliability, safety, and peak performance.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

If there is an issue they are quick to fix itVery good communication and fast responise times.This company always does what I ask.

They even find any errors that we may have made.

We have been dealing with this company for a number of years and have always recelved exemplary service.

I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

● ±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.