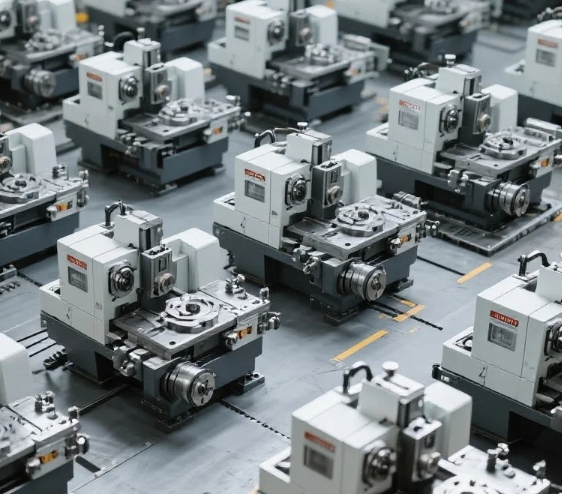

Rapid Prototyping CNC Grinding Machines for Large-Scale Mold Manufacturing

In today’s fast-paced manufacturing landscape, precision and efficiency are non-negotiable. For industries ranging from aerospace to automotive, the demand for large-scale mold manufacturing solutions hinges on advanced machinery that delivers both speed and micron-level accuracy. At PFT, we specialize in rapid prototyping CNC grinding machines engineered to meet these exacting standards.

Why Our CNC Grinding Machines Stand Out

1. Cutting-Edge Technology for Unmatched Precision

Our 5-axis CNC grinding machines, such as the PFG-730NC/CNC series, leverage linear motor drives and servo-controlled axes to achieve tolerances as tight as ±0.001mm. Equipped with Japanese NSK bearings and Taiwan-sourced HIWIN linear guides, these machines ensure stability even during high-speed operations . For industries requiring ultra-fine finishes, optional CBN (Cubic Boron Nitride) grinding wheels reduce heat generation, minimizing thermal distortion in hardened steel molds .

2. Scalability for Large-Scale Production

Designed for high-volume mold manufacturing, our machines feature worktables up to 700mm × 300mm (PFG-730NC) and can handle molds weighing over 3,500kg . The modular design of our HZ-KD series allows customization for grinding widths up to 2,500mm and lengths exceeding 14,000mm, making them ideal for automotive die components or industrial machinery bases .

3. Integrated Quality Control Protocols

Every component undergoes rigorous inspection using ISO 9001-certified processes. Our in-house quality lab employs coordinate measuring machines (CMMs) with 0.0001mm resolution to validate dimensional accuracy, while real-time SPC (Statistical Process Control) monitors tool wear and process stability . This ensures compliance with aerospace standards like AS9100 and medical device regulations such as ISO 13485.

4. Versatility Across Materials and Applications

From hardened tool steels (e.g., H13, D2) to aerospace-grade aluminum alloys, our machines adapt to diverse materials. The Hauser S45 CNC jig grinder in our lineup excels at complex geometries like S-shaped ball-end mills or multi-cavity molds, achieving surface finishes of Ra 0.1μm . Case studies include producing semiconductor templates with 0.002mm positional accuracy for ASM, a global leader in chip manufacturing .

5. End-to-End Support: From Prototyping to After-Sales

We don’t just sell machines—we partner with clients. Our engineers work closely with you during the rapid prototyping phase, optimizing cycle times using CAM simulations. Post-purchase, our 24/7 technical support team provides remote diagnostics and on-site maintenance, backed by a 2-year warranty on critical components like spindles and control systems .

Addressing Industry Pain Points

• Reduced Lead Times: Our machines slash mold development cycles by 75% compared to traditional EDM methods, as seen in projects for plastic injection mold clients .

• Cost Efficiency: By minimizing manual rework through precision grinding, we help clients like KingStar Mold cut defect-related costs by 30% .

• Supply Chain Transparency: Live production tracking via IoT-enabled systems ensures clients monitor progress in real time, mitigating delays .

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.