Precision Turned Components Factory

Product Overview

When you look at complex machines — from cars and medical devices to aircraft and industrial robots — it’s easy to focus on the big, visible parts. But behind every smooth-moving system lies a world of precision turned components that make it all work.

These tiny but vital parts are created in specialized facilities known as precision turned components factories, where accuracy isn’t optional — it’s everything.

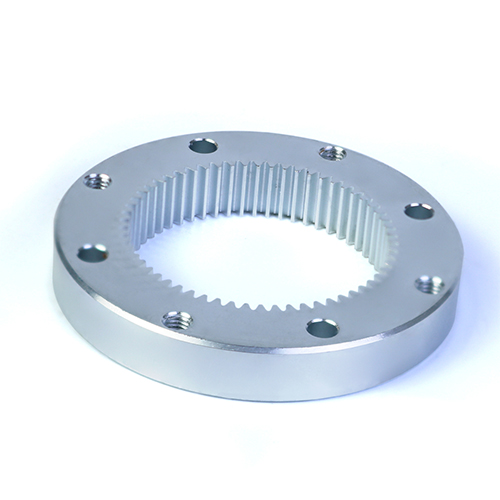

Precision turned components are metal or plastic parts produced through CNC turning or automatic lathe machining. The process involves rotating a bar of material while cutting tools shape it into the desired form. This technique can achieve extremely tight tolerances — often within microns — which is essential for industries that demand high precision and consistency.

Typical products include:

● Shafts and pins

● Fasteners and spacers

● Bushings and connectors

● Custom fittings and threaded parts

They may be small, but their role in ensuring mechanical stability, electrical conductivity, or fluid control is critical.

A modern precision turning factory combines advanced technology with skilled craftsmanship. Here’s what you can expect to find inside:

● CNC Turning Centers and Swiss-Type Lathes – The heart of production. These machines can handle multiple operations in one setup, reducing errors and boosting productivity.

● Material Expertise – From stainless steel and brass to aluminum, copper, and high-performance plastics, factories work with a wide range of materials.

● Inspection and Quality Control – Every component is checked using CMMs, optical projectors, and digital gauges to ensure it meets exact specifications.

● Secondary Operations – Threading, knurling, deburring, and surface finishing like anodizing or plating give components their final precision and appearance.

● Packaging and Delivery – Clean-room packing or bulk shipping, depending on the industry’s needs.

This combination of technology, quality management, and efficiency makes these factories the quiet force behind modern manufacturing.

Precision turned components are used everywhere. Some of the key sectors include:

● Automotive: Engine components, transmission fittings, and sensors.

● Aerospace: Lightweight, high-tolerance parts for aircraft systems.

● Medical: Surgical tools, implants, and precision assemblies.

● Electronics: Connectors, terminals, and housings.

● Industrial Machinery: Shafts, fasteners, and couplings.

Each of these industries demands not only accuracy but also reliability, which is why choosing the right precision turned components factory is so important.

If you’re sourcing precision turned components, here are a few points to consider:

● Certifications: Look for ISO 9001 or IATF 16949 accreditation.

● Experience: Factories with diverse industry experience often offer better problem-solving capabilities.

● Communication: A responsive supplier saves you time and avoids costly misunderstandings.

● Prototyping Support: Quick sample turnaround is a good sign of technical capability.

● Consistency: Ask about in-process inspections and batch testing.

A trustworthy manufacturer will be transparent about their process, materials, and quality systems.

Precision-machined parts may be small, but their impact is enormous. Behind every reliable product lies a factory dedicated to precision, innovation, and exquisite craftsmanship. Whether you are in the automotive, medical, or aerospace manufacturing industry, partnering with our factory ensures that your products operate precisely as designed every time.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

●Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

● If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

● They even find any errors that we may have made.

● We have been dealing with this company for a number of years and have always recelved exemplary service.

● I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

● Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

● ±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.