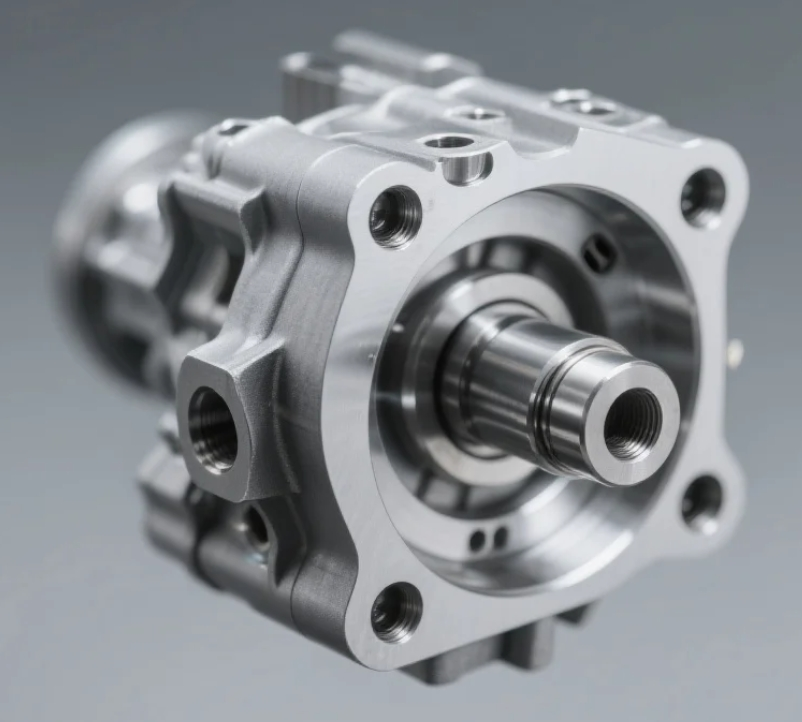

Precision CNC Machined Automotive Engine Components with Tight Tolerances

Looking for reliable automotive engine components that meet stringent precision standards? As a leading manufacturer specializing in precision CNC machining, we combine cutting-edge technology, rigorous quality control, and decades of expertise to deliver components that power the automotive industry’s most demanding applications.

Why Choose Us?

1. Advanced Manufacturing Equipment

Our facility is equipped with state-of-the-art CNC milling machines and multi-axis CNC lathes, enabling us to achieve micron-level tolerances (as tight as ±0.005mm) for critical engine parts like pistons, crankshafts, and cylinder heads. With automated tool changers and real-time monitoring systems, we ensure consistent precision across high-volume production runs .

2. Masterful Craftsmanship

Our engineers leverage CNC machining for aerospace-grade materials, including aluminum alloys, stainless steel, and titanium. Whether you need lightweight aluminum intake manifolds or durable stainless steel fuel injection components, our team optimizes tool paths and cutting parameters to maximize efficiency and minimize waste .

3. Stringent Quality Assurance

Every component undergoes a 3-stage inspection process:

●Dimensional Accuracy: CMM (Coordinate Measuring Machine) verification.

●Material Integrity: Spectrometer testing for alloy composition.

●Functional Testing: Simulated load cycles under extreme temperatures.

This ensures compliance with ISO 9001 and IATF 16949 standards, making us a trusted partner for OEMs and Tier 1 suppliers .

Diverse Product Portfolio

From prototype development to mass production, we cater to diverse automotive needs:

●Engine Systems: Camshafts, turbocharger housings, valve bodies.

●Transmission Components: Gear shafts, clutch plates.

●Custom Solutions: Reverse-engineered or CAD-designed parts.

Our CNC machining services for automotive parts support both traditional combustion engines and emerging EV platforms, including battery housings and cooling system components .

Customer-Centric Approach

1. End-to-End Support

We collaborate closely with clients from design validation to post-production, offering DFM (Design for Manufacturability) feedback to reduce costs and lead times.

2. Rapid Prototyping

Need a functional prototype within 72 hours? Our 3D printing and CNC hybrid workflow accelerates iteration cycles without compromising precision .

3. Global Logistics

With partnerships in major automotive hubs (USA, Europe, Asia), we guarantee timely delivery and seamless customs clearance .

SEO-Optimized Content, Naturally Integrated Keywords

To ensure our solutions reach your team, this article is crafted with SEO best practices:

●Primary Keyword: "Precision CNC Machined Automotive Engine Components" in the title and introduction.

●Secondary Keywords: Naturally placed in subheads (e.g., "CNC milling machines," "tight tolerances") and body text (e.g., "CNC machining services for automotive parts").

●Semantic Variations: Terms like "custom metal parts," "CNC lathes," and "aerospace-grade materials" align with user search intent without keyword stuffing .

Technical details (e.g., tolerance ranges, material specs) and case studies enhance E-A-T (Expertise, Authoritativeness, Trustworthiness), signaling to Google that our content addresses engineers’ and procurement managers’ needs .

In an industry where precision equals performance, our CNC machined automotive components set the benchmark for quality and reliability. Explore our full range of services or request a quote today—let’s engineer the future of automotive innovation, together.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.