On-Demand CNC Milling Services with Material Options

In today’s fast-paced manufacturing world, flexibility and speed are everything. Whether you're a product designer, engineer, or business owner, getting precision-machined parts quickly—without committing to massive production runs—can make all the difference. That’s where on-demand CNC milling services come in.

These services let you order custom parts with tight tolerances and a wide range of materials—right when you need them. No minimum order quantities. No tooling setup delays. Just precision parts, delivered fast.

What Is CNC Milling?

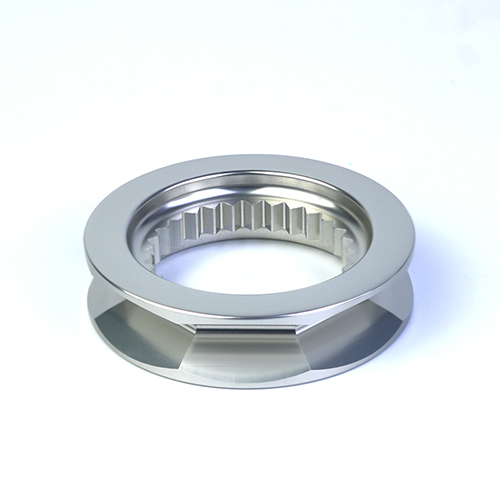

CNC (Computer Numerical Control) milling is a subtractive manufacturing process that uses rotating cutting tools to remove material from a solid block (known as a "workpiece") to create custom-designed parts. It’s ideal for creating parts with complex geometries and high precision.

Why Go On-Demand?

Traditionally, CNC machining was reserved for large-scale projects due to the cost of setup and tooling. But with the rise of on-demand manufacturing platforms, that’s changed.

Here’s why more businesses are switching to on-demand CNC milling:

● Faster Turnaround – Get parts in days, not weeks.

● Lower Costs – Only pay for what you need, when you need it.

● Rapid Prototyping – Test your designs quickly before going to full-scale production.

● Global Access – Order from anywhere and have parts shipped globally

● No Inventory Hassle – Eliminate the need to store large volumes of parts.

Material Options You Can Choose From

One of the biggest advantages of on-demand CNC milling is the wide selection of materials. Whether you need metal, plastic, or composites, there’s likely an option that fits your needs.

1.Metals

● Aluminum – Lightweight, corrosion-resistant, and ideal for aerospace, automotive, and consumer electronics.

● Stainless Steel – Strong, corrosion-resistant, and perfect for medical devices, tools, and marine parts.

● Brass – Easy to machine and offers good thermal and electrical conductivity.

●Titanium – Extremely strong yet lightweight, often used in aerospace and medical applications.

2.Plastics

● ABS – Tough and impact-resistant; great for functional prototypes.

● Nylon – Strong and wear-resistant, often used for mechanical components.

● POM (Delrin) – Low friction and great dimensional stability.

● Polycarbonate – Clear, tough, and often used for enclosures or protective covers.

3.Specialty Materials

Some providers even offer composites like carbon fiber-filled nylon or engineering plastics like PEEK, depending on your needs

Final Thoughts

Whether you're prototyping a new product or need high-quality components without the overhead of full-scale manufacturing, on-demand CNC milling is a smart solution. With fast lead times, plenty of material choices, and scalable production, it's never been easier to turn your ideas into real parts.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

●Simple prototypes: 1–3 business days

●Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

●3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

● ±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.