Company News

-

CNC Machining Tolerance Guide ±0.01mm: Achieving Precision in Manufacturing

Author: PFT Introduction: Why ±0.01mm Tolerance Matters in CNC Machining In high-precision industries such as aerospace, medical devices, and automotive engineering, achieving CNC machining tolerance of ±0.01mm is crucial. Even minor deviations can lead to part misalignment, assembly failure, or...Read more -

Best Materials for CNC Parts: Aerospace Grade

1 Introduction 1.1 Background High-performance CNC parts in aerospace applications require materials that combine low weight, high strength, and thermal stability. Aluminum, titanium, and nickel-based superalloys are predominant due to their favorable mechanical and chemical properties. Previous ...Read more -

How to Choose 5-Axis CNC Machining Service 2025

1. Introduction The demand for complex geometries and high-precision components in aerospace, automotive, and medical industries has driven widespread adoption of 5-axis CNC machining. Unlike traditional 3-axis operations, 5-axis machining allows simultaneous multi-directional cutting, reducing s...Read more -

CNC Machining Parts Factory: Latest Trends and Insights in Precision Manufacturing

In today’s fast-paced manufacturing industry, CNC machining parts factories play a pivotal role in producing high-precision components for sectors ranging from automotive and aerospace to medical devices. As demand for faster, more accurate, and cost-effective production grows, understanding the ...Read more -

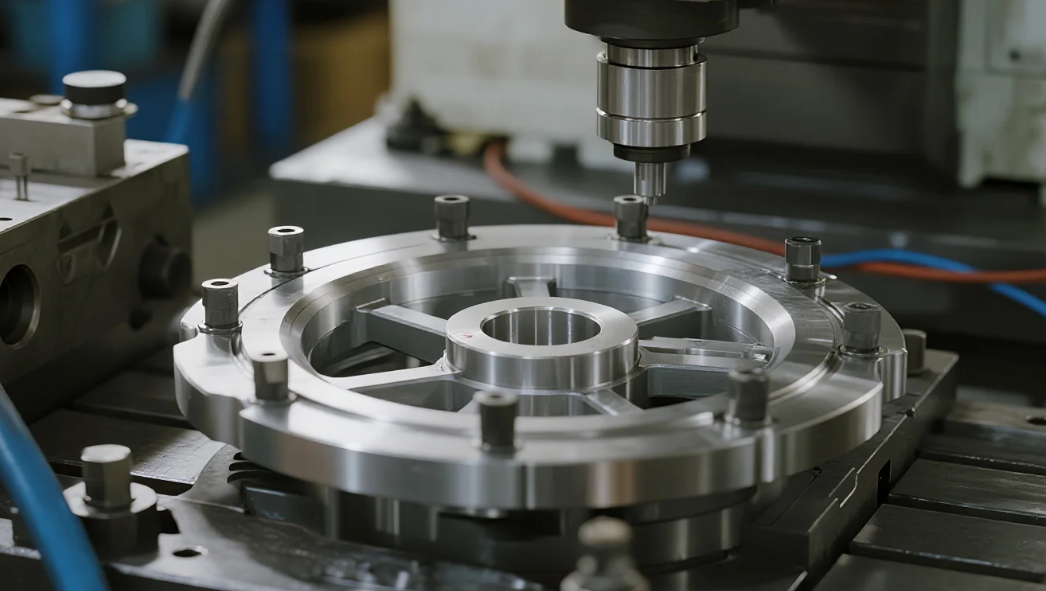

Five Key Processes for Improving CNC Turning Yields: Tools, Fixtures, Cooling, and In-Line Inspection

When customers place large-volume orders for precision CNC turned parts, the first question they often ask is: “Can you guarantee both high yield and consistent quality?” From our own production experience, we know that even a 2–3% improvement in yield can mean saving thousands of dollars in mate...Read more -

17-4PH vs. 304/316: A Practical Guide to Material Selection and Heat Treatment for Aerospace-Grade Parts

1 Research Method 1.1 Experimental Design The investigation was designed to provide reproducible comparison between precipitation-hardening and austenitic stainless steels. Three materials—17-4PH, 304, and 316—were procured from certified aerospace suppliers, each in rod form with identical diame...Read more -

Demand for Titanium Alloys in the Medical and Aviation Sector Continues to Grow

Why Titanium Alloys Are in High Demand If you’ve been sourcing raw materials or finished parts in recent years, you’ve likely noticed one clear trend: titanium alloys are becoming harder to ignore. From orthopedic implants to aircraft turbine blades, titanium is no longer a niche material—it’s ra...Read more -

Measured medical part data: ±0.005mm tolerance maintained

When it comes to medical devices, precision is not just a standard—it’s a matter of safety. In our factory, we recently completed a machining project where medical parts were measured with a maintained tolerance of ±0.005mm. This benchmark didn’t come easily; it required strict process control, r...Read more -

Five key criteria for selecting a CNC machining parts factory (quality, cost, delivery, capabilities, and certifications)

Choosing the right CNC machining parts factory can make or break your production efficiency and product quality. Whether you are sourcing parts for automotive, aerospace, or industrial machinery, understanding the key selection criteria is crucial. Based on our decade-long experience in CNC manuf...Read more -

Passed audits by aerospace customers, receiving high praise for its accuracy and stability.

When aerospace manufacturers evaluate suppliers, the first thing they look at is audit results. Passing an aerospace audit isn’t just about having paperwork in order — it’s a proof that the factory’s machining capability, quality control, and delivery reliability can stand up to the most demandin...Read more -

CNC machining parts factory – Is 3-axis, 4-axis, or 5-axis machining right for your parts?

1. Introduction The rapid growth of customized manufacturing demands precise and efficient machining solutions. CNC machines—ranging from 3-axis to 5-axis—offer distinct advantages for different part geometries. Understanding which CNC type aligns with production requirements is crucial for facto...Read more -

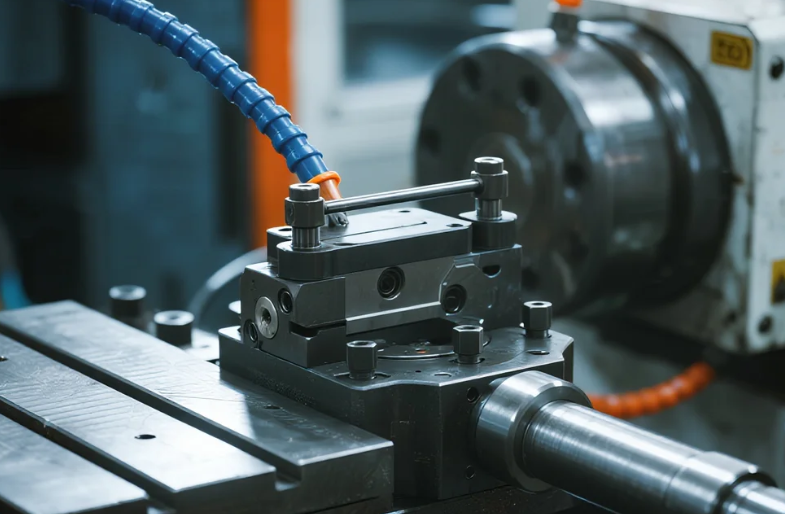

Upgraded High-Efficiency Tools Have Increased Stainless Steel Machining Efficiency by 20%

Why machining stainless steel has always been a challenge If you’ve ever run a CNC machine on stainless steel, you know the issues: tool wear happens fast, heat builds up quickly, and cutting speeds are often limited. In our factory, we used to face tool life dropping by nearly 30% compared with ...Read more