When engineers or buyers step into the world of CNC machining, the first question often is: Which process is right for my part? Milling, turning, and wire cutting are the three most common methods, but each operates on a different principle, delivers different tolerances, and fits specific applications. In our factory, these processes have been tested across aerospace components, medical implants, and precision molds, so what follows is a clear breakdown based on real shop-floor experience.

CNC Milling: Subtractive Flexibility

CNC milling works by using a rotating cutting tool that removes material as the workpiece stays fixed. It’s like sculpting with precision, layer by layer.

When we use milling in practice:

- Complex geometries: Our 5-axis mills can handle turbine blade contours, surgical tools, or custom housings.

- Material range: From hardened steels to lightweight aluminum alloys, milling maintains surface finish under tight tolerances.

- Best fit: Prototyping, multi-feature parts, or low-to-medium production runs where flexibility matters.

Experience insight: In one aerospace project, switching from 3-axis to 5-axis milling cut cycle time by 38% while reducing fixture changes from four setups down to one.

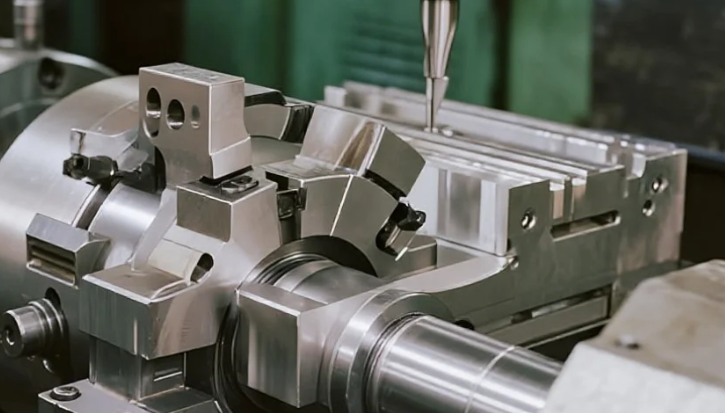

CNC Turning: The King of Cylindrical Parts

Turning, also known as lathe machining, rotates the workpiece while a stationary tool removes material. It’s highly efficient for parts with symmetry around a central axis.

When turning outperforms milling:

- Round parts: Shafts, bushings, medical screws, and threaded connectors.

- Speed: High RPM lathes make it the fastest option for simple geometries.

- Best fit: Mass production where cycle time per piece directly affects cost.

Experience insight: For a recent automotive shaft contract, CNC turning delivered 5,000 units with ±0.005 mm tolerance, keeping both delivery time and scrap rates under control.

Wire EDM (Wire Cutting): Precision Beyond Traditional Tools

Wire EDM (Electrical Discharge Machining) is a non-contact process that uses a thin electrically charged wire to cut through conductive materials. Unlike milling or turning, there is no physical cutting force—only sparks that erode material.

Where wire cutting shines:

- Extreme accuracy: Tolerances up to ±0.002 mm, ideal for dies and molds.

- Hard materials: Carbide, tool steel, and even exotic alloys that wear down conventional tools.

- Intricate shapes: Internal corners, fine slots, and features impossible with a rotating cutter.

Experience insight: In mold-making, we used wire EDM to create sharp internal radii of 0.1 mm that simply cannot be achieved on a mill without tool deflection.

Comparing the Three Processes

| Feature | Milling | Turning | Wire Cutting |

|---|---|---|---|

| Workpiece Motion | Fixed (tool moves) | Rotating (tool is fixed) | Fixed, cut by wire |

| Best For | Complex surfaces, prototypes | Cylindrical parts, high volume | High precision, hard materials |

| Tolerance Range | ±0.01 – 0.005 mm | ±0.01 – 0.005 mm | ±0.002 mm or tighter |

| Speed | Medium | Fast | Slower |

How to Choose the Right Process

- Prototype with complexity? Go for milling.

- Need thousands of round parts? Turning is unbeatable.

- Ultra-tight tolerances in hardened materials? Wire EDM is the solution.

From our factory’s experience, the best approach often combines all three. A part might be turned for its cylindrical base, milled for slots and contours, and finished with wire EDM for its fine details.

CNC machining is not just about technology—it’s about choosing the right process for the right stage of production. By understanding the fundamental differences between milling, turning, and wire cutting, engineers and sourcing managers can save both time and cost while achieving the level of precision their industry demands.

At the end of the day, the most successful projects we’ve run are those where we openly discuss tolerances, surface finish, and production volume before cutting a single piece of material. That’s where true value lies—not in the machine itself, but in the expertise behind it.

Post time: Aug-30-2025