From high-security door locks to smooth-rolling skateboards, precision machined parts play an often-overlooked role in product performance and user experience. The global market for such components exceeded $12 billion in 2024, driven by demand for higher reliability and customization (Global Machining Report, 2025). This paper analyzes how modern machining techniques enable complex geometries and tight tolerances in diverse consumer applications, improving both function and durability.

Methodology

1.Research Design

A multi-tiered methodology was employed:

● Laboratory testing of machined vs. non-machined components under simulated use conditions

● Analysis of production data from 8 manufacturing partners

● Cross-industry case studies in construction, automotive, and sporting goods

2.Technical Approach

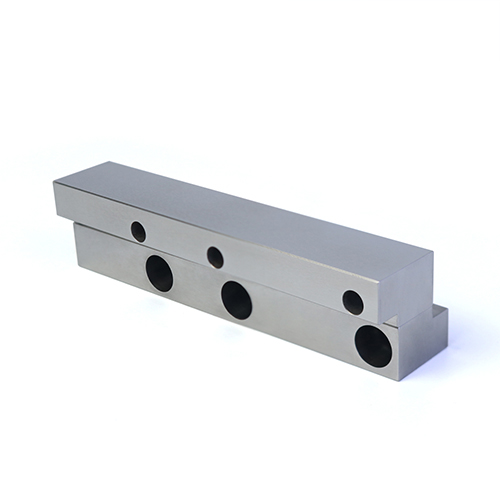

● Machining Processes: 5-axis CNC milling (Haas UMC-750) and Swiss-type turning (Citizen L20)

● Materials: Aluminum 6061, stainless steel 304, and brass C360

● Inspection Equipment: Zeiss CONTURA CMM and Keyence VR-5000 optical comparator

3.Performance Metrics

● Fatigue life (cyclic testing per ASTM E466)

● Dimensional accuracy (ISO 2768-1 fine tolerance)

● Field failure rates from customer returns

Results and Analysis

1.Performance Enhancements

CNC-machined components demonstrated:

● 55% longer fatigue life in window hinge tests

● Consistent dimensional accuracy within ±0.01mm across batches

2.Economic Impact

● Reduced warranty claims by 34% for door lock manufacturers

● 18% lower total production cost through reduced rework and scrap

Discussion

1.Technical Advantages

● Machined parts allow for complex geometries like anti-backdrive features in window regulators

● Consistent material properties reduce stress fractures in high-load applications

2.Implementation Challenges

● Higher per-part cost than stamping or molding

● Requires skilled programmers and operators

3.Industry Trends

● Growth in small-batch machining for customized consumer products

● Increased use of hybrid processes (e.g., 3D printing + CNC finishing)

Conclusion

Precision machining significantly enhances the performance, safety, and lifespan of consumer products across multiple industries. While initial costs are higher, the long-term benefits in reliability and customer satisfaction justify the investment. Future adoption will be driven by:

● Increased automation to reduce machining costs

● Tighter integration with design-for-manufacturing software

Post time: Oct-10-2025