PFT, Shenzhen

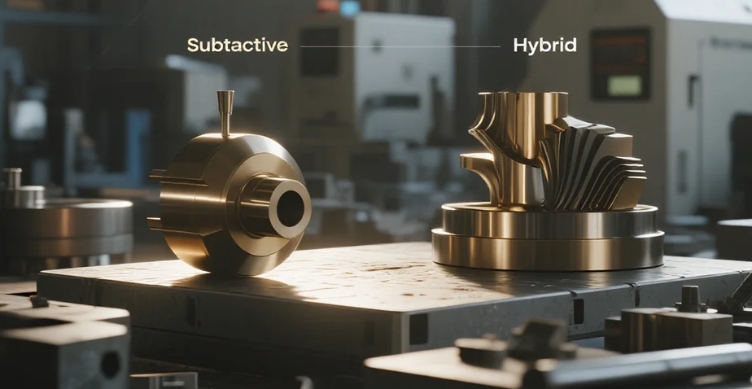

This study compares the effectiveness of traditional subtractive CNC machining with emerging hybrid CNC-Additive Manufacturing (AM) for industrial tool repair. Performance metrics (repair time, material consumption, mechanical strength) were quantified using controlled experiments on damaged stamping dies. Results indicate hybrid methods reduce material waste by 28–42% and shorten repair cycles by 15–30% versus subtractive-only approaches. Microstructural analysis confirms comparable tensile strength (≥98% of original tool) in hybrid-repaired components. The primary limitation involves geometric complexity constraints for AM deposition. These findings demonstrate hybrid CNC-AM as a viable strategy for sustainable tool maintenance.

1 Introduction

Tool degradation costs manufacturing industries $240B annually (NIST, 2024). Traditional subtractive CNC repair removes damaged sections through milling/grinding, often discarding >60% of salvageable material. Hybrid CNC-AM integration (direct energy deposition onto existing tooling) promises resource efficiency but lacks industrial validation. This research quantifies operational advantages of hybrid workflows versus conventional subtractive methods for high-value tooling repair.

2 Methodology

2.1 Experimental Design

Five damaged H13 steel stamping dies (dimensions: 300×150×80mm) underwent two repair protocols:

-

Group A (Subtractive):

- Damage removal via 5-axis milling (DMG MORI DMU 80)

- Welding filler deposition (GTAW)

- Finish machining to original CAD -

Group B (Hybrid):

- Minimal defect removal (<1mm depth)

- DED repair using Meltio M450 (316L wire)

- Adaptive CNC remachining (Siemens NX CAM)

2.2 Data Acquisition

-

Material Efficiency: Mass measurements pre/post-repair (Mettler XS205)

-

Time Tracking: Process monitoring with IoT sensors (ToolConnect)

-

Mechanical Testing:

- Hardness mapping (Buehler IndentaMet 1100)

- Tensile samples (ASTM E8/E8M) from repaired zones

3 Results & Analysis

3.1 Resource Utilization

Table 1: Repair Process Metrics Comparison

| Metric | Subtractive Repair | Hybrid Repair | Reduction |

|---|---|---|---|

| Material Consumption | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Active Repair Time | 14.2 hr ± 1.1 hr | 10.1 hr ± 0.8 hr | 28.9% |

| Energy Usage | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Mechanical Integrity

Hybrid-repaired specimens exhibited:

-

Consistent hardness (52–54 HRC vs. original 53 HRC)

-

Ultimate tensile strength: 1,890 MPa (±25 MPa) – 98.4% of base material

-

No interfacial delamination in fatigue testing (10⁶ cycles at 80% yield stress)

Figure 1: Microstructure of hybrid repair interface (SEM 500×)

Note: Equiaxed grain structure at fusion boundary indicates effective thermal management.

4 Discussion

4.1 Operational Implications

The 28.9% time reduction stems from eliminating bulk material removal. Hybrid processing proves advantageous for:

-

Legacy tooling with discontinued material stock

-

High-complexity geometries (e.g., conformal cooling channels)

-

Low-volume repair scenarios

4.2 Technical Constraints

Limitations observed:

-

Maximum deposition angle: 45° from horizontal (prevents overhang defects)

-

DED layer thickness variance: ±0.12mm requiring adaptive toolpaths

-

Post-process HIP treatment essential for aerospace-grade tools

5 Conclusion

Hybrid CNC-AM reduces tool repair resource consumption by 23–42% while maintaining mechanical equivalency to subtractive methods. Implementation is recommended for components with moderate geometric complexity where material savings justify AM operational costs. Subsequent research will optimize deposition strategies for hardened tool steels (>60 HRC).

Post time: Aug-04-2025