As industries race to meet the rising demand for precision, customization, and fast production cycles, a new tool is taking center stage in professional manufacturing: the CNC laser engraver. Once reserved for small-scale shops and design studios, CNC laser engraving technology is now being adopted across large-scale manufacturing sectors, from aerospace to electronics and consumer goods.  Precision Meets Productivity

Precision Meets Productivity

CNC laser engravers offer unmatched precision and flexibility, making them an increasingly essential asset in professional manufacturing environments. Controlled by advanced computer programming, these machines use focused laser beams to engrave, etch, or cut materials with micron-level accuracy — all without direct contact.

A Tool for Every Industry

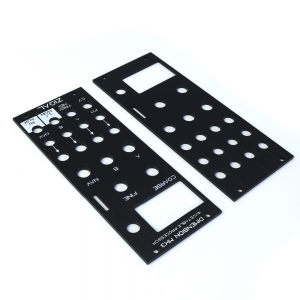

Professional manufacturers across sectors are integrating CNC laser engravers into their production processes:

• Automotive: Etching serial numbers, QR codes, and logos on engine parts and dashboards. • Medical Devices: Laser engraving barcodes and part IDs on surgical instruments and implants for compliance and tracking.

• Electronics: Precision engraving of component labels and intricate circuit board layouts. • Consumer Goods: Personalizing products such as jewelry, electronics, and sporting gear at mass scale.

This versatility has made CNC laser engraving indispensable for both branding and functional part marking — two growing priorities in automated production.

Material Capabilities Expanding

Modern CNC laser engravers can process a wide range of materials, including:

• Metals (aluminum, stainless steel, brass)

• Plastics (ABS, polycarbonate, acrylic)

• Wood and composites

• Glass and ceramics

With the introduction of fiber and diode lasers, manufacturers now have the power to engrave hard materials with minimal heat distortion, making the technology ideal for delicate or high-precision components.

The Role of Automation and AI

As part of the Industry 4.0 revolution, CNC laser engravers are increasingly integrated with automated conveyor systems, robotic arms, and AI-powered quality control. Smart systems now analyze engraved patterns in real time, reducing defects and increasing throughput.

A Green Manufacturing Option

Laser engraving is also proving to be more sustainable than traditional marking methods. Unlike ink or chemical etching, laser engraving produces minimal waste and requires no consumables. That aligns with the growing push for eco-friendly professional manufacturing practices.

Looking Ahead

With the market for customized and serialized products continuing to grow, CNC laser engravers are poised to play an even larger role in global manufacturing. Emerging developments — including 3D surface engraving, ultra-fast galvanometer systems, and integrated IoT diagnostics — are making the machines smarter, faster, and more adaptable.

Post time: Jun-28-2025