As global industries strive for greater efficiency, durability, and precision in product development, CNC metal cutting has emerged as a critical pillar of professional manufacturing. From aerospace components to medical devices and automotive systems, manufacturers are relying on advanced CNC (Computer Numerical Control) metal cutting technologies to deliver unparalleled quality at scale.  CNC Metal Cutting: A Foundation for Modern Industry

CNC Metal Cutting: A Foundation for Modern Industry

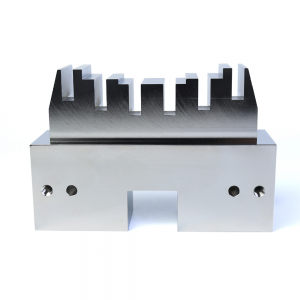

CNC metal cutting refers to the use of computer-controlled machinery to shape and remove material from metal workpieces. Utilizing advanced lathes, mills, lasers, and plasma cutters, CNC systems provide unmatched accuracy, repeatability, and speed.

Driving Innovation in Key Sectors

CNC metal cutting has transformed manufacturing across a range of industries:

• Aerospace: Complex titanium components, turbine parts, and structural brackets are precision-machined to withstand high stress and temperature conditions.

• Automotive: Engine blocks, transmission housings, and brake components are milled with exacting standards for mass production.

• Medical Technology: Surgical tools, orthopedic implants, and diagnostic equipment frames are cut from stainless steel and titanium with biocompatible finishes.

• Energy Sector: CNC machines produce precision-fitted parts for turbines, pipelines, and battery enclosures with high durability requirements.

Professional manufacturers now use CNC metal cutting to ensure quality consistency, improve efficiency, and reduce lead times — all essential in highly competitive global markets.

Technology Behind the Transformation

CNC metal cutting involves several high-tech processes, including:

• Milling and Turning: Remove metal using rotary tools or lathes, suitable for complex shapes and tight tolerances.

• Laser Cutting: Uses high-powered lasers to melt or vaporize metal with extreme precision — ideal for thin sheets and intricate designs.

• Plasma Cutting: Employs ionized gas to cut thicker or conductive metals quickly and efficiently.

• Wire EDM (Electrical Discharge Machining): Enables ultra-precise cuts on hardened metals without applying direct force, often used in tool and die manufacturing.

With the addition of multi-axis machining, AI-powered monitoring, and digital twins, today’s CNC metal cutting machines are more intelligent and flexible than ever before.

Smart Manufacturing and Sustainability

Modern CNC metal cutting systems are designed for automation and sustainability. They integrate seamlessly with robotics and factory management software, enabling lights-out manufacturing and real-time quality assurance. Additionally, improvements in tool efficiency and material utilization are helping reduce waste and energy consumption.

Post time: Jun-28-2025