As global industries increasingly demand components that are both highly precise and rapidly produced, manufacturers are turning to advanced machining solutions to maintain competitiveness. By 2025, CNC turning has evolved from a specialized process to a central manufacturing strategy, enabling the production of complex, high-tolerance parts with shorter cycle times and greater flexibility. This shift is particularly evident in sectors such as electric vehicle manufacturing, surgical instrument production, and telecommunications infrastructure, where part quality and production agility are critical.

What Is CNC Turning?

CNC turning is a subtractive manufacturing process where a computer-controlled lathe rotates a workpiece while a cutting tool shapes it into the desired form. It’s primarily used for cylindrical or round parts, but modern machines allow for highly complex geometries with multi-axis capabilities.

The process can handle a wide range of materials, including:

● Stainless steel

● Aluminum

● Brass

● Titanium

● Plastics and composites

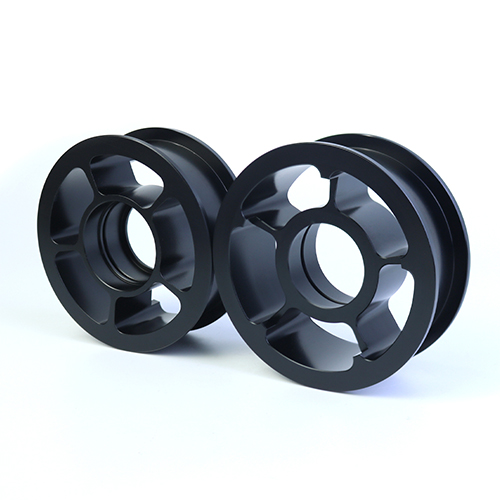

CNC turning services are often used for creating components like:

● Shafts and pins

● Bushings and bearings

● Nozzles and connectors

● Housings and sleeves

Results and Analysis

1. Precision and Surface Quality

CNC turning with adaptive toolpaths and live tooling consistently held tolerances within ±0.005 mm and achieved surface roughness values between Ra 0.4–0.8 μm.

2. Production Speed and Flexibility

Integration of automated pallet changers and robotic part handling reduced average cycle time by 35–40% and allowed rapid changeover between production batches.

3. Scalability and Cost Efficiency

High-volume production runs demonstrated near-linear scalability without loss of precision, while small batches benefited from reduced setup time and minimal manual intervention.

Discussion

1. Interpretation of Outcomes

The precision and speed advantages of modern CNC turning are largely attributable to advancements in machine rigidity, spindle design, and closed-loop feedback systems. Scalability is enhanced through integration with manufacturing execution systems (MES) and IoT-enabled machine monitoring.

2. Limitations

This study focused on turning centers from three manufacturers; performance may vary with machine age, controller type, and tooling budget. Economic factors such as energy consumption and initial investment were not central to this analysis.

3. Practical Implications

CNC turning is particularly suitable for manufacturers seeking to combine high part quality with rapid response to market changes. Industries requiring complex geometries—such as hydraulics, optics, and defense—can significantly benefit from adopting or expanding turning capabilities.

Key Industries Driving Growth

● Aerospace: High-performance shafts, fasteners, and housings require extreme precision and material integrity.

●Automotive: CNC-turned components are found in suspension systems, gear assemblies, and engine parts.

● Medical Devices: Surgical tools, implants, and connectors benefit from the fine detail and material compatibility CNC turning offers.

● Oil & Gas: Durable parts like flanges, valves, and casings depend on the strength and accuracy of CNC turning.

● Consumer Products: Even luxury goods—like watches and pens—leverage CNC-turned parts for durability and visual appeal.

Final Thoughts

Whether you’re launching a new product or upgrading your supply chain, CNC turning services offer a proven path to faster production, better quality, and scalable growth.

As industries shift toward precision-driven manufacturing, CNC turning is more than just a machining method—it’s a competitive advantage.

Post time: Aug-27-2025