Imagine creating intricate metal filigree, wooden carvings , or aerospace components with the consistency of a master artisan – but 24/7. That’s the reality at our factory since we integrated state-of-the-art CNC carving machines.

Why Precision Matters in Modern Manufacturing

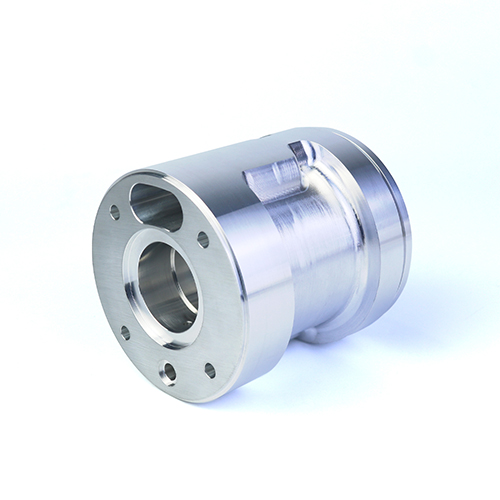

Traditional carving methods struggle with microscopic details. Our CNC machines maintain 0.005-0.01mm accuracy – thinner than a human hair . For clients needing:

● Medical device components

● Luxury furniture inlays

● Customized automotive trim

This means zero tolerance errors. One aerospace customer saw defective part rates drop from 3.2% to 0.4% post-implementation.

Customization Unleashed

Remember when “custom orders” meant 6-week delays? Our system handles design changes in minutes.

How it works:

● Upload 3D designs (CAD files accepted)

● Machines auto-adjust toolpaths

● Switch materials seamlessly: aluminum → hardwood → acrylic

We recently produced 17 completely unique architectural panels in a single batch – previously impossible.

Behind the Tech:

● Automated Tool Changes: 12-second bit swaps handle delicate engraving and heavy milling

● Smart Sensors: Real-time vibration correction prevents microscopic flaws

● Dust Extraction: Eco-friendly filters capture 99.3% particulates

What Clients Notice

● Surface Perfection: Mirror finishes without polishing

● Complex Geometry: Undercuts & 3D contours in solid metal

● Consistency: Identical replication of heritage restoration pieces

Post time: Jul-10-2025