News

-

Measured medical part data: ±0.005mm tolerance maintained

When it comes to medical devices, precision is not just a standard—it’s a matter of safety. In our factory, we recently completed a machining project where medical parts were measured with a maintained tolerance of ±0.005mm. This benchmark didn’t come easily; it required strict process control, r...Read more -

Five key criteria for selecting a CNC machining parts factory (quality, cost, delivery, capabilities, and certifications)

Choosing the right CNC machining parts factory can make or break your production efficiency and product quality. Whether you are sourcing parts for automotive, aerospace, or industrial machinery, understanding the key selection criteria is crucial. Based on our decade-long experience in CNC manuf...Read more -

Passed audits by aerospace customers, receiving high praise for its accuracy and stability.

When aerospace manufacturers evaluate suppliers, the first thing they look at is audit results. Passing an aerospace audit isn’t just about having paperwork in order — it’s a proof that the factory’s machining capability, quality control, and delivery reliability can stand up to the most demandin...Read more -

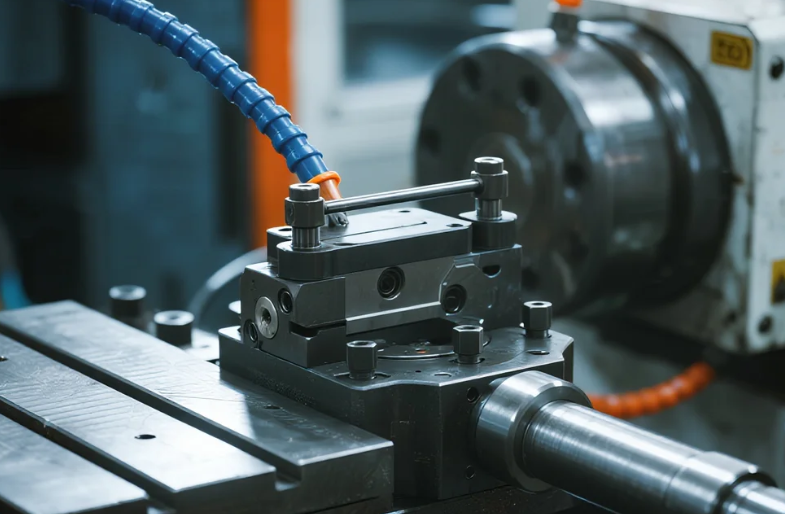

CNC machining parts factory – Is 3-axis, 4-axis, or 5-axis machining right for your parts?

1. Introduction The rapid growth of customized manufacturing demands precise and efficient machining solutions. CNC machines—ranging from 3-axis to 5-axis—offer distinct advantages for different part geometries. Understanding which CNC type aligns with production requirements is crucial for facto...Read more -

Upgraded High-Efficiency Tools Have Increased Stainless Steel Machining Efficiency by 20%

Why machining stainless steel has always been a challenge If you’ve ever run a CNC machine on stainless steel, you know the issues: tool wear happens fast, heat builds up quickly, and cutting speeds are often limited. In our factory, we used to face tool life dropping by nearly 30% compared with ...Read more -

How can you reduce procurement costs and delivery risks by using a CNC machining parts factory?

1. Selecting the Right CNC Machining Parts Factory Key Factors to Consider: Certifications & Quality Standards: Look for ISO 9001, AS9100, or industry-specific certifications to ensure consistent quality. Equipment & Technology: Factories with advanced multi-axis CNC machines (3, 4, 5...Read more -

How to Select Materials and Estimate Costs: Comparing the Advantages and Disadvantages of Stainless Steel, Aluminum, and Brass for CNC Turning

When planning a CNC turning project, material selection is more than just a technical decision—it directly impacts machining efficiency, production cost, and final product performance. Many engineers and buyers ask: Should I choose stainless steel, aluminum, or brass for CNC turning? In this guid...Read more -

New standards for aerospace parts machining have been introduced: How should CNC factories respond?

1 Introduction The aerospace industry operates under some of the strictest machining standards worldwide. Recently introduced updates place greater emphasis on data-driven quality assurance, surface performance consistency, and traceability across machining steps. For CNC factories, these changes...Read more -

How to Cut CNC Machining Cycle Time with High-Efficiency Toolpaths (HEM/HSC)

PFT, Shenzhen Date: September 2025 Introduction: Mastering CNC Productivity Reducing CNC machining cycle time is a challenge every manufacturing engineer faces. Using High-Efficiency Milling (HEM) and High-Speed Cutting (HSC) toolpaths can significantly accelerate production while maintaining s...Read more -

How to Prevent Rust on CNC Beds and Ways in Humid Environments

PFT, Shenzhen Abstract High humidity accelerates corrosion on CNC machine beds and ways, leading to reduced precision, increased maintenance costs, and shortened equipment lifespan. This study investigates protective strategies against rust formation under humid conditions. Methods include contr...Read more -

How to Implement Predictive Maintenance for CNC Coolant Pumps on a Budget

I still remember that morning on the shop floor. I could hear a strange hum from one of our CNC coolant pumps—low, metallic, almost like a subtle warning. When I touched the pump casing, it was warmer than usual, a tiny clue that something wasn’t right. That day, a minor coolant leak could have e...Read more -

Ceramic 3D Printing vs Slip Casting for Heat-Resistant Insulators (Geometry Freedom & Density)

1. Ceramic 3D Printing: Unlocking Design Freedom What It Is Ceramic 3D printing, also known as additive manufacturing, builds components layer by layer using ceramic slurries, pastes, or powders. This method is ideal for creating complex geometries that are impossible or cost-prohibitive with tra...Read more