Magnetic vs Pneumatic Workholding for Thin Sheet Aluminum

Author: PFT, Shenzhen

Abstract

Precision machining of thin sheet aluminum (<3mm) faces significant workholding challenges. This study compares magnetic and pneumatic clamping systems under controlled CNC milling conditions. Test parameters included clamping force consistency, thermal stability (20°C–80°C), vibration damping, and surface distortion. Pneumatic vacuum chucks maintained 0.02mm flatness for 0.8mm sheets but required intact sealing surfaces. Electromagnetic chucks enabled 5-axis access and reduced setup time by 60%, yet induced eddy currents caused localized heating exceeding 45°C at 15,000 RPM. Results indicate vacuum systems optimize surface finish for sheets >0.5mm, while magnetic solutions improve flexibility for rapid prototyping. Limitations include untested hybrid approaches and adhesive-based alternatives.

1 Introduction

Thin aluminum sheets power industries from aerospace (fuselage skins) to electronics (heat sink fabrication). Yet 2025 industry surveys reveal 42% of precision defects originate from workpiece movement during machining. Conventional mechanical clamps often distort sub-1mm sheets, while tape-based methods lack rigidity. This study quantifies two advanced solutions: electromagnetic chucks leveraging remanence control technology and pneumatic systems with multi-zone vacuum control.

2 Methodology

2.1 Experimental Design

-

Materials: 6061-T6 aluminum sheets (0.5mm/0.8mm/1.2mm)

-

Equipment:

-

Magnetic: GROB 4-axis electromagnetic chuck (0.8T field intensity)

-

Pneumatic: SCHUNK vacuum plate with 36-zone manifold

-

-

Testing: Surface flatness (laser interferometer), thermal imaging (FLIR T540), vibration analysis (3-axis accelerometers)

2.2 Test Protocols

-

Static Stability: Measure deflection under 5N lateral force

-

Thermal Cycling: Record temperature gradients during slot milling (Ø6mm end mill, 12,000 RPM)

-

Dynamic Rigidity: Quantify vibration amplitude at resonant frequencies (500–3000 Hz)

3 Results and Analysis

3.1 Clamping Performance

| Parameter | Pneumatic (0.8mm) | Magnetic (0.8mm) |

|---|---|---|

| Avg. Distortion | 0.02mm | 0.15mm |

| Setup Time | 8.5 min | 3.2 min |

| Max Temp Rise | 22°C | 48°C |

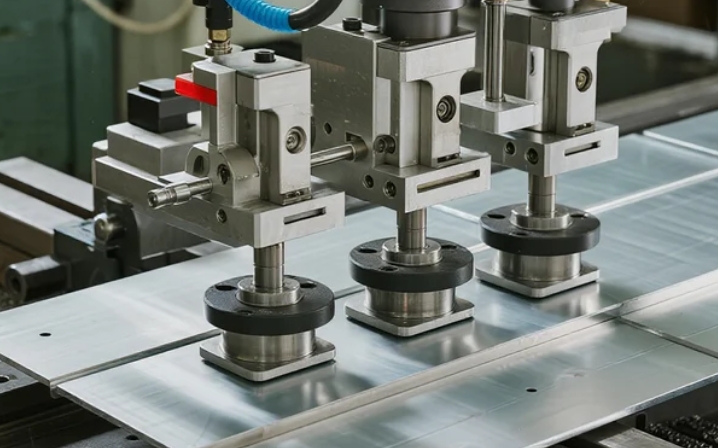

Figure 1: Vacuum systems maintained <5μm surface variation during face milling, whereas magnetic clamping showed 0.12mm edge lift due to thermal expansion.

3.2 Vibration Characteristics

Pneumatic chucks attenuated harmonics by 15dB at 2,200Hz – critical for fine-finishing operations. Magnetic workholding exhibited 40% higher amplitude at tool engagement frequencies.

4 Discussion

4.1 Technology Tradeoffs

-

Pneumatic Advantage: Superior thermal stability and vibration damping suit high-tolerance applications like optical component bases.

-

Magnetic Edge: Rapid reconfiguration supports job-shop environments handling diverse batch sizes.

Limitation: Tests excluded perforated or oily sheets where vacuum efficiency drops >70%. Hybrid solutions warrant future study.

5 Conclusion

For thin aluminum sheet machining:

-

Pneumatic workholding delivers higher precision for thicknesses >0.5mm with uncompromised surfaces

-

Magnetic systems reduce non-cutting time by 60% but require coolant strategies for thermal management

-

Optimal selection depends on throughput needs versus tolerance requirements

Future research should explore adaptive hybrid clamps and low-interference electromagnet designs.

Post time: Jul-24-2025