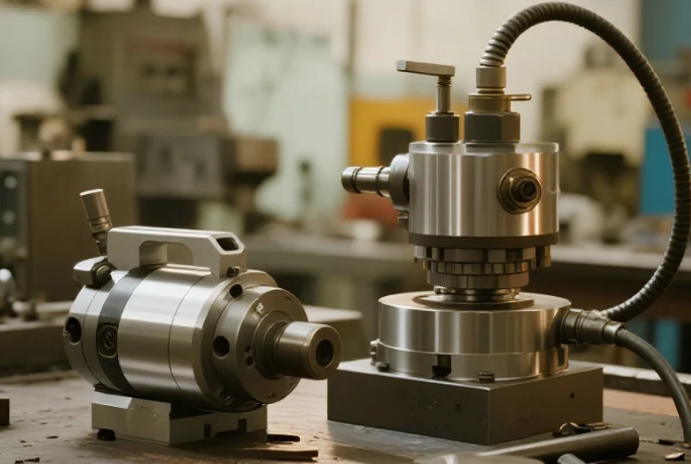

The high-pitched hiss of compressed air cuts through the hum of your CNC mill. You watch as a pneumatic clamp (powered by compressed air) snaps shut, securing a steel block in seconds. It feels quick, almost eager.

Across the aisle, a hydraulic clamp (powered by oil pressure) engages with a deep, resonant thunk. Its movement is deliberate, powerful, leaving no doubt about its grip on that massive cast iron part.

You need new clamps for a demanding production run. That familiar question surfaces: Air or oil? Let’s cut through the fog.

Core Differences: Speed vs. Power

At their core, both systems aim to hold workpieces rock-solid.

-

Pneumatics rely on shop air—convenient and fast. Think of it like a sprinter: quick off the mark.

-

Hydraulics use incompressible oil, delivering immense, unwavering force—more like a weightlifter holding a record lift.

Key Considerations:

-

Clamping Force Consistency

-

Pneumatic pressure fluctuates with line pressure and leaks.

-

Hydraulics lock in force with near-perfect rigidity.

-

Why does this matter? Imagine precision boring a delicate aluminum housing. Any tiny shift ruins it. Hydraulics excel here.

-

-

Speed vs. Strength

-

Loading dozens of small parts per hour? Pneumatics win on cycle time.

-

Need massive holding power in a tight space? Hydraulics deliver force a pneumatic cylinder three times its size couldn’t match.

-

-

Creep (Gradual Force Loss)

The Trade-Offs: Convenience vs. Performance

Here’s the kicker: Convenience isn’t free.

Pneumatics: Quick & Simple

✔ Plug-and-play (hooks into existing air lines)

✔ Lower upfront cost

✖ Battles moisture (needs dryers & filters)

✖ Air leaks (listen for that tell-tale hiss!)

✖ Less efficient (compressed air wastes energy)

Hydraulics: Power & Precision

✔ Unmatched force & rigidity

✔ No creep, even under heat/load

✔ Better force-to-size ratio

✖ Needs a power unit (pump, reservoir, cooling)

✖ Messy leaks (oil spills = safety/environmental risk)

✖ Higher maintenance (contamination kills valves)

How to Decide? Ask These Questions

Break it down ruthlessly:

-

Force & Rigidity Needed?

-

Brute strength (milling tough alloys)? → Hydraulic

-

Lighter duty, fast cycling? → Pneumatic

-

-

Environment & Duty Cycle?

-

Dirty, wet shop? → Pneumatics tolerate grime better

-

Clean room, 24/7 heavy load? → Hydraulics endure

-

-

Infrastructure & Budget?

-

Got dry air lines? → Pneumatics integrate easily

-

Prepared for hydraulic power unit costs? → Hydraulics win on power density

-

-

Safety & Control?

-

Hydraulics lock position without constant pressure (critical fail-safe).

-

Pneumatics need steady air supply.

-

Final Verdict: No Universal Winner

-

Choose Pneumatics for:

-

Speed, simplicity, moderate force

-

Fast cycling, lower initial cost

-

-

Choose Hydraulics for:

-

Unbeatable power & rigidity

-

Extreme precision, heavy-duty, or harsh environments

-

Listen beyond the hiss and the thunk. What does your production truly demand? Choose the grip that won’t let you down.

Your bottom line depends on it.

Post time: Aug-14-2025