When people talk about CNC machining, they usually mean one of three core processes: milling, turning, or wire EDM. These methods form the backbone of modern precision manufacturing. Whether you are sourcing custom components for aerospace, automotive, or medical devices, understanding the differences between these machining types helps you choose the right solution, save costs, and ensure long-term reliability of your parts.

At our own facility, we’ve run thousands of jobs using each of these processes. The practical insights below come not just from textbooks, but from years of tool breakages, tolerance battles, and customer audits that shaped how we run CNC today.

CNC Milling: Complex Geometries Made Repeatable

CNC milling is often the first thing that comes to mind when people picture machining. A rotating cutting tool removes material from a stationary block (the workpiece) to create shapes, slots, holes, and surface finishes.

Real-world example: In our shop, we use 5-axis milling centers to produce aerospace brackets with ±0.005 mm accuracy. These parts often require multiple angles and undercuts—geometries that traditional 3-axis setups simply cannot achieve efficiently.

When to use milling:

-

Parts with complex 3D geometries (medical implants, turbine components)

-

Jobs requiring fine surface finishes and micro features

-

Medium-to-high production runs where repeatability is critical

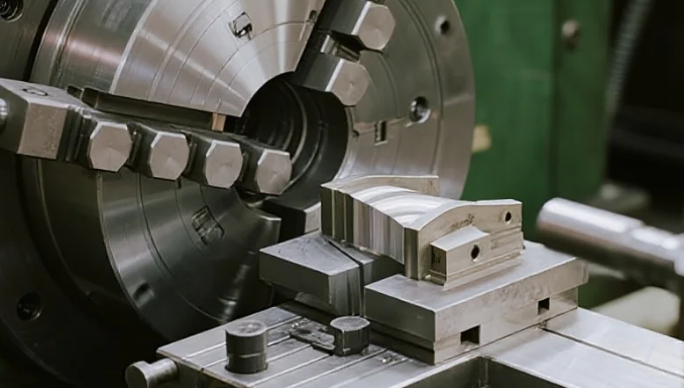

CNC Turning: Precision for Cylindrical Parts

Turning is the opposite of milling. Instead of a rotating tool, the workpiece itself spins on a lathe while cutting tools remove material. This makes turning ideal for cylindrical shapes like shafts, pins, and bushings.

Shop-floor insight: We often run stainless steel shafts up to 600 mm length on multi-axis turning centers. Live tooling allows us to add milled features—keyways, threads, and cross-holes—without a secondary setup, reducing lead times dramatically.

When to use turning:

-

Round parts with tight concentricity requirements

-

High-speed production of threaded components

-

Cost-effective runs of axles, bolts, or housings

Wire EDM: Ultra-Precise Cuts Without Tool Pressure

Wire EDM (Electrical Discharge Machining) is a completely different approach. Instead of cutting with physical contact, a thin wire electrode uses controlled sparks to erode material. The result is extremely accurate cuts with no mechanical stress on the workpiece.

Our experience: For hardened tool steels and carbide inserts, milling tools wear out quickly. With wire EDM, we routinely achieve ±0.002 mm tolerances and perfect inside corners—features impossible with rotary tools.

When to use wire EDM:

-

Hard or delicate materials where tool wear is a problem

-

Intricate shapes like dies, molds, and medical instruments

-

Applications demanding sharp internal corners and stress-free cutting

Choosing the Right Process

Each CNC method has its strengths:

-

Milling → best for complex, prismatic parts

-

Turning → best for round, symmetric components

-

Wire EDM → best for ultra-precise, hard-material profiles

In practice, most production lines use a combination. For example, we might turn a shaft for concentricity, mill slots for assembly, and finish with EDM for internal details. This hybrid approach ensures both cost efficiency and engineering performance.

CNC machining isn’t just about machines—it’s about choosing the right process for the right job. Milling, turning, and wire EDM each solve different problems, and experienced shops often blend them to achieve the best results.

For engineers and procurement teams, knowing these distinctions allows better design-for-manufacturing decisions, smoother supplier communication, and fewer surprises when the first parts come off the machine.

If you’re looking to source CNC parts, consider not just what you need but how it should be made. The process choice could be the difference between a part that passes inspection on the first run—or one that burns through time, cost, and patience.

Post time: Aug-31-2025