We’re excited to announce the latest upgrade to our machining capabilities with the addition of a state-of-the-art 5-axis CNC milling machine. This powerful equipment is now fully operational at our facility and is already being used for high-precision projects across aerospace, medical, and custom industrial applications.

What Makes 5-Axis Machining Different?

Unlike traditional 3-axis machines , which move a tool along just the X, Y, and Z axes, a 5-axis CNC milling machine adds two more rotational axes — allowing the cutting tool to approach the workpiece from virtually any direction.

This not only opens up new possibilities for complex geometries but also helps reduce setup times, improve surface finishes, and maintain tighter tolerances. For clients, this translates into better-quality parts, faster turnaround times, and reduced production costs.

Why We Made the Upgrade

As part of our commitment to investing in advanced manufacturing, we chose to bring 5-axis capability in-house to meet growing demand for intricate and high-performance parts. Many of our clients in the aerospace and medical sectors have been requesting more complex components with multi-face machining — and this upgrade lets us deliver those with higher efficiency and consistency.

Our new machine allows us to:

● Mill multiple sides in one setup – reducing clamping and repositioning errors

● Achieve tighter tolerances – critical for mating components or dynamic parts

● Speed up lead times – because fewer setups mean faster part delivery

● Handle more complex parts – ideal for prototypes and low- to mid-volume runs

Real-World Applications

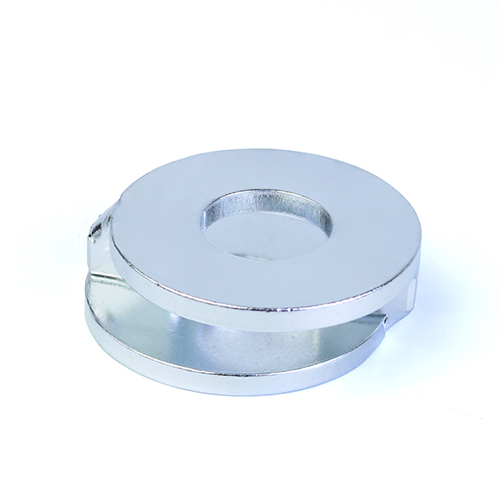

Since the installation, we’ve already completed projects involving titanium brackets for aerospace customers, surgical-grade stainless steel implants, and aluminum housings for custom automation systems. The feedback so far? Quicker deliveries, smoother finishes, and consistent repeatability.

Looking Ahead

We see the 5-axis CNC milling machine not just as a piece of equipment, but as a tool that allows us to better support engineers, designers, and product teams who are building the future. Whether it’s a prototype that demands precision or a short-run production order with complex geometry, we now have the tools in-house to get it done.

Post time: Jul-10-2025