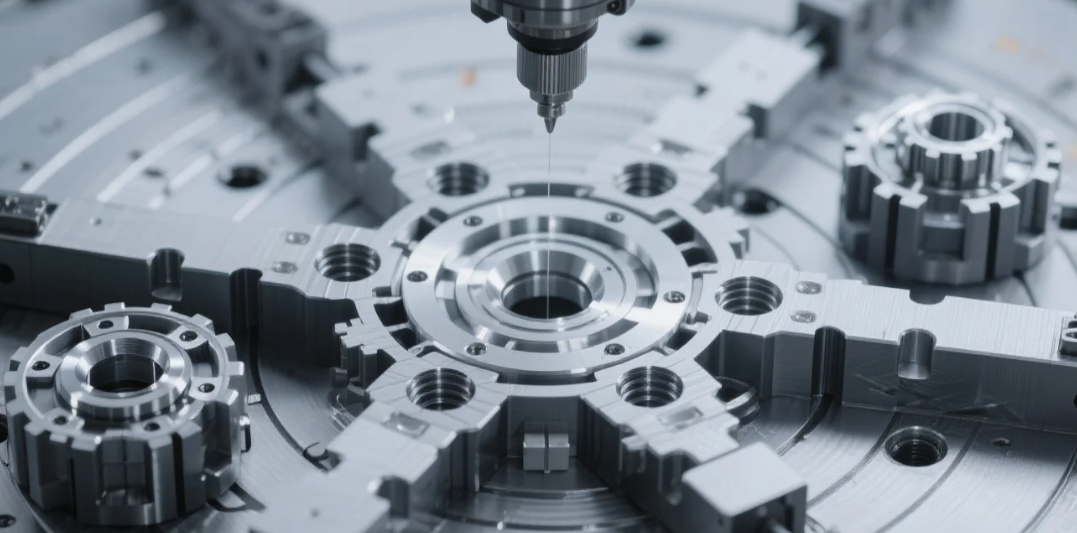

Multi-Axis CNC Machining for Ultra-Precision Optical Components with Complex Geometries

In industries where micron-level accuracy defines success—aerospace, medical devices, advanced optics—the demand for ultra-precision optical components with complex geometries is surging. Traditional 3-axis CNC machines struggle with intricate contours and tight tolerances, but multi-axis CNC machining revolutionizes this. Our factory leverages cutting-edge 5-axis CNC technology to deliver components that meet the most rigorous standards, combining advanced equipment, rigorous quality control, and tailored customer support .

Why Multi-Axis CNC Machining?

1.Unmatched Precision for Complex Designs

• Unlike 3-axis machines limited to linear movements, our 5-axis CNC systems (e.g., DMU series) enable simultaneous rotation along A/B/C axes. This allows machining complex shapes—freeform lenses, aspherical mirrors—in a single setup, eliminating repositioning errors and achieving tolerances within ±0.003mm .

• Example: A dual-curvature lens for laser collimators, requiring <0.005mm surface deviation, was produced with 99.8% accuracy .

2.Efficiency & Cost Savings

• Single-setup machining reduces production time by 40–60% versus multi-stage processes. For a satellite optical housing project, we cut lead time from 14 days to 6 .

• Automated toolpaths minimize material waste—critical for expensive substrates like fused silica or Zerodur® .

Our Factory’s Unique Capabilities

1. Advanced Multi-Axis Equipment

- 5-Axis CNC Centers: DMU 65 monoBLOCK® (travel: X-1400mm, Y-900mm, Z-700mm; spindle: 42,000 RPM) for high-speed, vibration-free finishing .

- Ultra-Precision Add-Ons: Integrated laser probes for real-time metrology and adaptive toolpath correction during machining .

- In-Process Monitoring: Every component undergoes three checkpoints:

2. Rigorous Quality Ecosystem

Raw material spectrometry (ISO 17025-certified lab) .

On-machine probing for dimensional accuracy .

Post-process CMM validation (Zeiss CONTURA G2, accuracy: 1.1µm + L/350µm) .

• ISO 9001/13485 Compliance: Documented workflows ensure traceability from design to delivery .

3. Diverse Material & Application Expertise

Materials: Optical glass, ceramics, titanium, Inconel®.

Applications: Endoscopes, VR lens arrays, fiber-optic collimators, aerospace reflectors .

4. End-to-End Customer Support

• Design Collaboration: Our engineers optimize designs for manufacturability (DFM)—e.g., simplifying undercuts to reduce costs .

• Post-Delivery Assurance:

o 24/7 technical hotline (<30-min response) .

o Lifetime maintenance support + 2-year warranty .

o Spare-part logistics: Global delivery within 72 hours .

Case Study: High-NA Microscope Objective Lens

Challenge: A biomedical client needed 200 lenses with micro-grooves (depth: 50µm ±2µm) for fluidic light-guiding.

Solution:

• Our 5-axis CNC programmed elliptical toolpaths with variable tilt angles.

• In-process laser scanning detected deviations >1µm, triggering auto-correction.

Result: 0% rejection rate; 98% on-time delivery .

FAQs: Addressing Key Customer Concerns

Q: Can you handle geometries with undercuts or non-rotational symmetry?

A: Absolutely. Our 5-axis CNC’s tilt-rotary tables access angles up to 110°, machining features like helical channels or off-axis parabolic surfaces without refixturing .

Q: How do you ensure optical surface integrity?

A: We use diamond-coated tools with nano-polishing cycles, achieving surface roughness (Ra) <10nm—critical for laser applications .

Q: What if I need design modifications post-production?

A: Our cloud-based portal lets you submit revisions, with updated prototypes delivered in 5–7 days .

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.