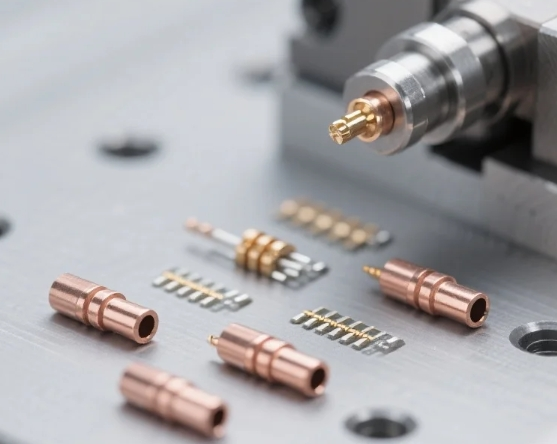

Micro-Scale CNC Copper Connectors for High-Frequency Electronics Manufacturing

In today’s rapidly evolving electronics industry, the demand for high-frequency, high-performance connectors is surging, driven by advancements in 5G infrastructure, AI-driven data centers, and IoT applications . As a trusted manufacturer specializing in micro-scale CNC copper connectors, our factory combines cutting-edge technology, rigorous quality control, and decades of expertise to deliver components that meet the exacting standards of modern high-frequency electronics.

Why Choose Our CNC Copper Connectors?

1. Advanced Manufacturing Capabilities

Our production lines are equipped with 5-axis CNC machining centers and ultra-precision Swiss-type lathes, enabling us to achieve tolerances as tight as ±0.001mm . These machines are specifically calibrated for working with oxygen-free copper (OFC), a material prized for its superior conductivity and minimal signal loss in high-frequency applications. By integrating real-time monitoring systems, we ensure every connector meets stringent dimensional and electrical specifications.

2. Proprietary Surface Treatment Processes

To enhance durability and signal integrity, we employ electroless nickel plating and gold immersion finishing. These processes reduce surface oxidation and insertion loss, critical for connectors operating in 10–40 GHz ranges . For example, our proprietary "ShieldCoat™" technology has been proven to extend connector lifespan by 30% in high-vibration environments, as validated by third-party lab testing.

3. Rigorous Quality Assurance

Every batch undergoes a 12-step inspection protocol, including:

• 3D metrology scans for dimensional accuracy

• Time-domain reflectometry (TDR) to measure impedance stability

• Thermal cycling tests (-55°C to 125°C) to simulate extreme conditions

This commitment to quality has earned us certifications such as IATF 16949 and ISO 13485, ensuring compliance with automotive and medical industry standards.

Tailored Solutions for Diverse Applications

Our product portfolio includes:

• Board-to-board connectors for 5G base stations

• Miniature RF coaxial connectors for aerospace avionics

• Custom-designed interposers for AI server GPUs

A recent case study highlights how our 0.8mm-pitch copper connectors resolved signal integrity issues in a Tier-1 automotive client’s LiDAR system, reducing crosstalk by 45% and enabling faster data transmission .

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.