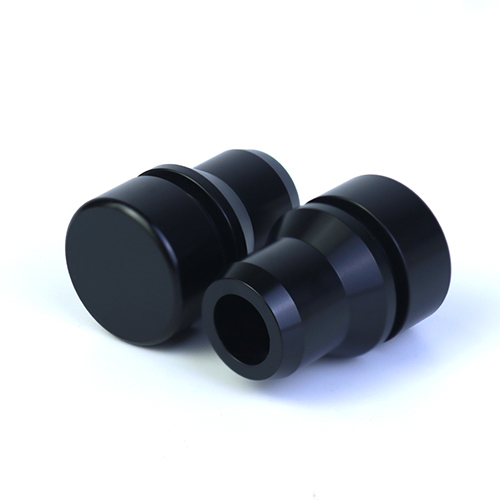

Metal CNC Machine

In the modern era of industrial innovation, where precision, speed, and consistency define success, the metal CNC machine stands as a cornerstone of professional manufacturing. From aerospace and automotive to medical devices and energy systems, businesses across the globe rely on CNC (Computer Numerical Control) technology to produce complex, high-performance metal components with exceptional accuracy. As a symbol of professional-grade production, the metal CNC machine is increasingly the quality choice for manufacturers committed to excellence.

Professional Manufacturing: Built for Demanding Industries

Professional manufacturing using metal CNC machines involves more than just automation—it reflects a commitment to quality, efficiency, and innovation. Key characteristics of professional-grade CNC machining include:

Advanced Machinery: High-speed spindles, multi-axis control (3-, 4-, and 5-axis), and rigid construction allow machines to handle complex geometries and hard metals with ease.

Engineering Expertise: Skilled technicians and engineers oversee programming, setup, and quality assurance, ensuring each component meets strict industry standards.

Precision and Consistency: Whether producing one part or ten thousand, CNC machines deliver consistent results with tolerances often within microns.

Streamlined Workflow: From digital design to final inspection, the production process is optimized for minimal waste, reduced lead times, and enhanced productivity.

Professional manufacturing with metal CNC machines is the backbone of industries where safety, performance, and reliability cannot be compromised.

Why Metal CNC Machines Are the Quality Choice

When quality is non-negotiable, a metal CNC machinebecomes the preferred solution. Here’s why:

1. Unmatched Accuracy

CNC machines are capable of producing intricate components with extreme precision. Tolerances as tight as ±0.001 mm ensure compatibility with complex assemblies and high-stress environments.

2. Material Versatility

From lightweight aluminum to hardened tool steel, metal CNC machines can handle a broad range of materials, making them suitable for diverse applications and industries.

3. Scalability

CNC machining is ideal for both low-volume prototyping and high-volume production, offering flexibility without sacrificing quality or turnaround time.

4. Reduced Human Error

The automated process significantly reduces the risk of mistakes, enhancing safety and reducing rework, while maintaining the integrity of each part.

5. Superior Surface Finish

Advanced cutting tools and controlled feed rates result in smooth surfaces and refined finishes—often eliminating the need for additional post-processing.

Applications Across Industries

Metal CNC machines are trusted in industries where failure is not an option:

Aerospace: Turbine blades, structural brackets, and landing gear components.

Automotive: Engine blocks, gearboxes, and suspension components.

Medical: Surgical tools, implants, and diagnostic device parts.

Defense: Precision firearm components, armor parts, and tactical equipment.

Energy: Oil and gas fittings, turbine parts, and heat exchangers.

Each application requires components that can withstand extreme conditions—both in terms of performance and manufacturing standards. Metal CNC machining delivers on both fronts.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

They even find any errors that we may have made.

We have been dealing with this company for a number of years and have always recelved exemplary service.

I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

Simple prototypes: 1–3 business days

Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

3D CAD files (preferably in STEP, IGES, or STL format)

2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

±0.005" (±0.127 mm) standard

Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.