Manufacturing process in mechanical Engineering

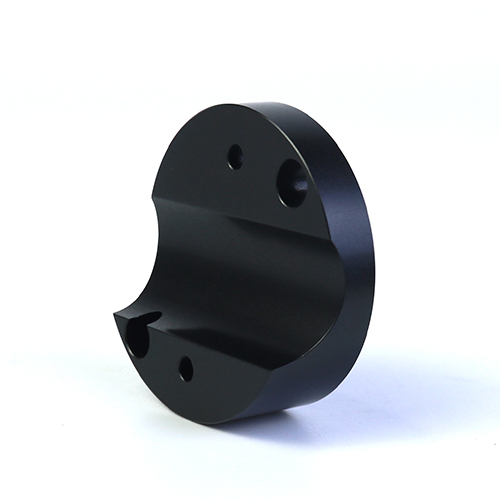

Product Overview

Hey there, curious minds! If you've ever held a smartphone, driven a car, or even used a simple door hinge, you've interacted with the amazing world of mechanical manufacturing.

It’s the behind-the-scenes magic that turns ideas into tangible, functional things.

But what does that process actually look like? If you picture a sweaty blacksmith with a hammer, you're only seeing a tiny part of the picture! Today, let's demystify some of the core methods engineers use to make the parts that make our world work.

1. The "Take Away" Method: Machining

This is probably what most people imagine. You start with a solid block of material (like aluminum or steel), and you carefully remove bits of it until you get the shape you want. It’s like a super-precise, computerized version of whittling wood.

(a spinning cutter shaves the material) and Turning

● (the material spins while a stationary cutter shapes it, common for making round parts like shafts).

● The Vibe: Highly accurate, fantastic for creating complex shapes and smooth finishes. Perfect for making prototypes or low-volume, high-precision parts.

● The Catch: It can be slow and wasteful. All that material you cut away? That's scrap (though we recycle it!).

2. The "Squeeze and Form" Method: Metal Forming

Instead of taking material away, this process reshapes it by applying force. Think of it like play-doh, but for super-strong metals.超链接:(https://www.pftworld.com/)

Common Techniques:

● Forging: Hammering or pressing metal into a die. This aligns the metal's grain structure, making it incredibly strong. This is how wrenches and crankshafts are made.

● Stamping: Using a punch and die to cut or form sheet metal. Your car's body panels and the metal case of your laptop are almost certainly stamped.

● The Vibe: Excellent strength, high production speed, and very little material waste.

● The Catch: The initial tooling (the dies and molds) can be very expensive, so it's best for high-volume production.

3. The "Melting and Molding" Method: Casting

This is one of the oldest tricks in the book. You melt the material (often metal or plastic) and pour it into a hollow mold. Let it cool and solidify, and voilà—you have your part.

● Common Technique: Die Casting is a popular one, where molten metal is forced under high pressure into a reusable steel mold.

● The Vibe: Ideal for creating complex, intricate shapes that would be too difficult or expensive to machine. Think of engine blocks, complex gearbox housings, or even a simple metal toy.

● The Catch: While the parts themselves are cheap to produce at scale, the molds are pricey. The process can also sometimes introduce tiny internal weaknesses like pores or inclusions.

4. The "Join the Team" Method: Joining & Fabrication

Many products aren't a single piece; they're an assembly of many parts. This is where joining comes in.

Common Techniques:

● Welding: Fusing materials together by melting them at the joint, often adding a filler material. It creates a super-strong, permanent bond.

● Adhesive Bonding: Using high-strength industrial glues. It's great for distributing stress and joining different materials (like metal to composite).

● The Vibe: Essential for creating large structures (ships, bridges, pipelines) and complex assemblies.

● The Catch: Welding can weaken the base material around the weld if not done correctly, and adhesive bonding requires careful surface preparation.

You can't talk about modern manufacturing without mentioning 3D printing.

Unlike machining (which is subtractive), 3D printing is additive. It builds a part layer by layer from a digital file.

● The Vibe: Unbeatable for complex geometries (like internal cooling channels), rapid prototyping, and custom one-off parts. It creates almost zero waste.

● The Catch: It can be slower for mass production, and the material properties aren't always as strong as those from forging or casting—yet! The technology is improving every day.

This is the million-dollar question! The truth is, there's no single winner. The choice depends on a perfect storm of factors:

● What's the part for? (Does it need to be super strong? Lightweight?)

● What material is it made from?

● How many do we need to make? (One, a thousand, or a million?)

● What's the budget and timeline?

A good mechanical engineer is like a chef. They don't just know one recipe; they know all the tools and ingredients and how to combine them to create the perfect final product.

Next time you pick up any engineered object, take a second to look at it. See if you can guess which of these processes brought it to life. It’s a fascinating world hiding in plain sight!

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

● Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

● If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

● They even find any errors that we may have made.

● We have been dealing with this company for a number of years and have always recelved exemplary service.

● I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

● Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.