High Precision Parts Machining Suppliers

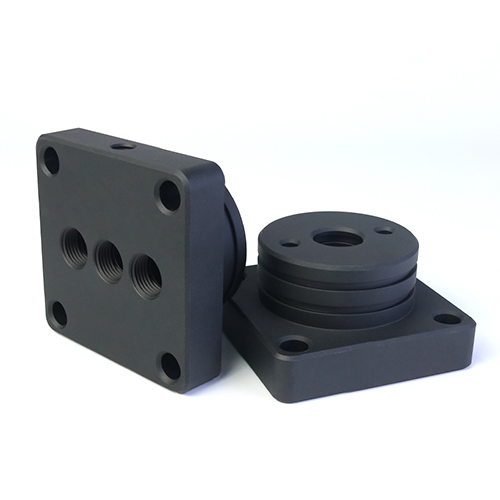

Product Overview

Frankly, if you're searching for "high-precision parts machining suppliers," you're not just buying parts; you're investing in the final product.

Even the smallest error, a deviation of only a fraction of a millimeter, can ruin an entire project. We're talking about parts used in medical devices, aerospace systems, and critical R&D prototypes. The risk is extremely high, and the margin for error is zero.

High precision parts machining refers to the process of using advanced equipment and technology to produce parts with extremely tight tolerances—often within fractions of a millimeter or micron range. These parts are typically made using CNC (Computer Numerical Control) machines, which are capable of executing highly accurate movements based on computer-generated designs.

Some key operations involved in high precision machining include:

● CNC Milling and Turning: Used to shape parts with complex geometries or cylindrical forms.

● EDM (Electrical Discharge Machining): A process for creating highly intricate shapes or hard materials that are difficult to machine with traditional methods.

● Grinding and Polishing: For achieving smooth finishes and exact dimensions.

These methods are used to manufacture parts that meet the strictest standards, including those in aerospace, automotive, medical, and electronics industries.

When you're sourcing high precision parts, your choice of supplier can significantly impact your production efficiency, product quality, and even your bottom line. Working with the right machining supplier ensures:

● High-Quality Products: Precision machining suppliers who have the right expertise and equipment can deliver parts that meet your exacting specifications.

● On-Time Delivery: Delays in the supply chain can wreak havoc on your production schedule. A reliable supplier who can deliver parts on time is invaluable.

● Cost-Effective Solutions: While high-precision machining can be expensive, a good supplier can help you find cost-efficient solutions without compromising quality.

● Design Flexibility: The best suppliers offer design support and are capable of making adjustments to meet evolving production needs.

The right supplier doesn’t just manufacture parts—they help optimize the production process and ensure that you meet the demands of your customers without setbacks.

When choosing a supplier for high precision parts machining, there are several key factors to keep in mind. Here’s what to look for to ensure you’re partnering with the best.

1. Advanced Equipment and Technology

To achieve the level of precision required, your supplier needs to have cutting-edge equipment. This includes CNC milling machines, CNC lathes, wire EDM machines, and other high-precision tools that can achieve tight tolerances and complex geometries.

● Multi-axis CNC Machines: Machines with 3, 4, or 5 axes allow for more complex part geometries and precision work. This is especially important for industries like aerospace or medical, where intricate designs are the norm.

● Wire EDM Machines: These machines are essential for cutting extremely hard materials and creating intricate details that standard machining tools can't handle.

Check the supplier’s capabilities to see if they are equipped to handle the complexity and precision your parts require.

2. Experience and Expertise

Machining high-precision parts isn't something every supplier can do. It takes experience, knowledge, and skill to consistently produce parts within the tight tolerances required in industries like aerospace or medical manufacturing.

A supplier with a solid track record and experience in your industry will be able to:

● Understand the specific challenges of your application.

● Offer recommendations to optimize your part designs for manufacturability.

● Ensure that their processes align with industry standards and regulations (e.g., ISO certifications, AS9100 for aerospace, or FDA compliance for medical devices).

It’s always a good idea to ask for case studies, testimonials, or client references to gauge the supplier's level of expertise and their ability to handle complex projects.

3. Quality Control and Certifications

Quality control is critical when it comes to high precision machining. Even a small deviation in tolerance can result in a part that’s unusable or fails to meet safety standards. Look for a supplier that has strict quality control protocols in place, such as:

● ISO 9001 Certification: This global standard ensures that the supplier is committed to maintaining quality management practices.

● In-house Inspection: Ask about the tools and processes the supplier uses for measuring and inspecting parts, such as CMM (Coordinate Measuring Machines) or laser scanners. These tools can help verify that parts meet exact specifications before they are shipped out.

A good supplier will also be able to provide you with inspection reports and documentation for each batch of parts they produce.

4. Turnaround Time and Delivery Reliability

In manufacturing, time is money. Choosing a supplier who can meet your deadlines is just as important as choosing one who can deliver high-quality parts. Look for a supplier who:

● Has a proven track record of on-time delivery.

● Provides clear communication about lead times and any potential delays.

● Has the ability to scale production if needed for larger orders or quick-turnaround jobs.

Suppliers with automated workflows and robust production scheduling systems tend to be more reliable in meeting deadlines and adapting to changes in demand.

5. Flexibility and Customization

High precision parts machining often involves unique or customized components that can’t be mass-produced. Whether you need one-off prototypes or small to medium production runs, it’s important to work with a supplier who is flexible and capable of adapting to your needs.

● Prototyping Capabilities: Can the supplier create prototypes for testing and validation before full production?

● Design Assistance: Do they offer engineering support to refine your designs and ensure they’re optimized for manufacturability?

A supplier who can work with you through every stage—from design to final production—can make a huge difference in the success of your project.

6. Competitive Pricing

High precision machining can be costly due to the specialized equipment and expertise required. While you don’t want to compromise on quality, it’s still important to find a supplier who offers competitive pricing. Be sure to:

● Request clear, detailed quotes that outline all costs involved, including setup, machining, and finishing.

● Consider long-term partnerships. Sometimes, committing to larger or recurring orders can lead to price breaks and better overall value.

Don’t just go for the cheapest option—look for a supplier that balances cost, quality, and reliability.

Choosing a high-precision machining supplier is a critical decision. Don't just shop based on the lowest price. Partner with a team that demonstrates the expertise, equipment, and—most importantly—the obsessive attention to detail that your project demands.

Your innovation deserves a foundation that's built to perfection.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

● Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

● If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

● They even find any errors that we may have made.

● We have been dealing with this company for a number of years and have always recelved exemplary service.

● I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

● Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

●±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.