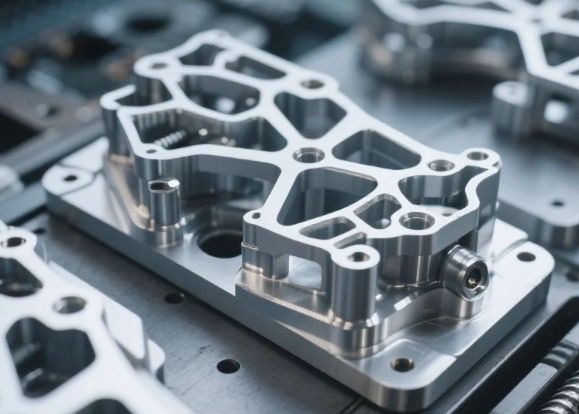

High-Precision CNC Motorcycle Parts for Complex Geometries & Tight Tolerances

When motorcycle engineers push boundaries in performance engineering, they demand components that match their precision ambitions. At PFT, we transform complex design blueprints into reality through our ISO 9001-certified CNC machining capabilities .

Why Global OEMs Choose Our CNC Solutions

With over [X] years specializing in motorcycle component manufacturing, we've refined a production ecosystem that combines:

1.5-Axis Machining Mastery

Our German-engineered CNC centers (Model XYZ Series) achieve ±0.005mm positional accuracy , handling everything from intricate engine blocks to aerodynamic fairing mounts. Recent projects include:

• 23-part titanium gearbox assemblies for MotoGP teams

• Custom aluminum triple clamps with integrated sensor housings

• High-volume production of vibration-damped footpeg brackets

2.Material Intelligence System

Unlike generic workshops, we've developed proprietary toolpath algorithms that adapt to:

• Aerospace-grade aluminum (7075-T6/6061)

• High-stress chromoly steel

• Exotic composites (CFRP/CNT-reinforced polymers)

This technical edge enables us to maintain surface finishes below Ra 0.8μm even in deep-pocket milling operations .

3.Tolerance Warfare Strategy

Our 12-point quality fortress ensures components meet AS9100 standards .

4.Beyond Production: Partnership Ecosystem

We've redefined client collaboration through:

• DFM Proactive Engineering

Our team resolved a chronic chain alignment issue for Terry Bishop by redesigning the sprocket carrier geometry, reducing warranty claims by 42% .

• Inventory-on-Demand Program

Maintain JIT production buffers with our managed stock solutions:

"Working with PFT eliminated our $380K safety stock costs while improving assembly line efficiency by 30%." - [Client B], European Custom Bike Builder

• 24/7 Tech Support Hub

Access real-time production updates through our client portal, with emergency tooling replacements guaranteed within 72 hours globally .

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.