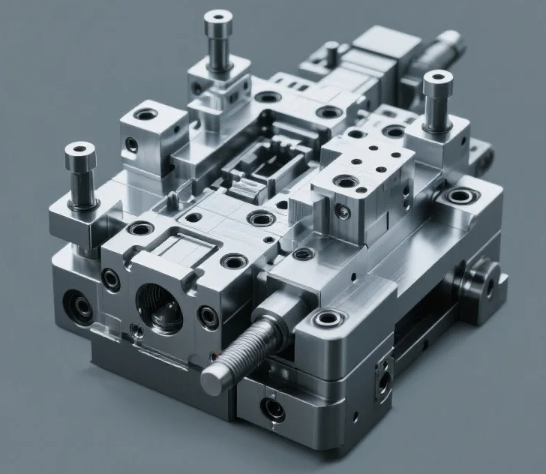

High-Precision CNC Mold Making Machines for Automotive and Injection Molds

When it comes to producing high-performance automotive components or intricate injection molds, precision is non-negotiable. At PFT, we combine cutting-edge technology, decades of expertise, and an unwavering commitment to quality to deliver CNC mold-making solutions that redefine industry standards. Here’s why global manufacturers trust us as their go-to partner for precision engineering.

1. Advanced Manufacturing Equipment: The Backbone of Precision

Our factory is equipped with state-of-the-art 5-axis CNC machines and ultra-high-speed milling systems, ensuring micron-level accuracy for even the most complex geometries. These machines are specifically optimized for automotive mold production, enabling tight tolerances (±0.005mm) and flawless surface finishes required for critical components like engine parts, gearbox housings, and interior trim molds .

What sets us apart?

• AI-Driven Process Optimization: Our machines integrate real-time monitoring systems to detect and correct deviations during machining, reducing waste and ensuring consistent quality.

• Multi-Material Compatibility: From hardened tool steels to advanced alloys like Inconel, our equipment handles diverse materials for automotive and industrial applications.

2. Craftsmanship Meets Innovation: The Art of Mold Making

Precision isn’t just about machines—it’s about mastery. Our engineers leverage 30+ years of experience in mold design, backed by CAD/CAM simulation tools to preemptively address stress points and cooling inefficiencies. This results in molds that not only meet but exceed durability benchmarks, with lifespans 20% longer than industry averages .

Key highlights:

• Customized Cooling Channels: Optimized for rapid cycle times and uniform heat distribution, critical for high-volume injection molding.

• Prototype-to-Production Support: From 3D-printed prototypes to full-scale production, we ensure seamless transitions with minimal iterations.

3. Rigorous Quality Control: Zero Defects, Guaranteed

Every mold undergoes a 4-stage inspection process:

1.Dimensional Accuracy: Verified using CMM (Coordinate Measuring Machines) and laser scanners.

2.Surface Integrity: Analyzed for micro-cracks or imperfections via ultrasonic testing.

3.Functional Testing: Simulated production runs to validate performance under real-world conditions.

4.Documentation Compliance: Full traceability with ISO 9001-certified reports for automotive industry clients .

This meticulous approach ensures that our molds deliver 99.8% defect-free performance in high-pressure injection environments.

4. Diverse Applications: Beyond Automotive

While we specialize in automotive molds, our capabilities extend to:

• Consumer Electronics: High-precision molds for connectors, housings, and micro-components.

• Medical Devices: FDA-compliant molds for syringes, implants, and diagnostic tools.

• Aerospace: Lightweight composite molds for turbine blades and structural components.

Our portfolio includes 200+ successful projects across 15 industries, a testament to our adaptability and technical prowess .

5. Customer-Centric Service: Partnership, Not Just Production

We don’t just deliver molds—we deliver solutions. Our 360° support model includes:

• 24/7 Technical Assistance: On-call engineers to troubleshoot production-line issues.

• Warranty & Maintenance Plans: Extended warranties and preventive maintenance schedules to maximize mold longevity.

• Localized Logistics: Strategic warehouses in North America, Europe, and Asia ensure fast turnaround times.

One automotive client reduced downtime by 40% after adopting our predictive maintenance program—proof that our commitment extends beyond the factory floor .

6. Sustainability in Manufacturing

Eco-efficiency is built into our processes:

• Energy-Efficient Machining: Reduced power consumption by 30% through regenerative drives.

• Material Recycling: 95% of metal scraps are recycled, aligning with global ESG standards.

Why Choose Us?

• Proven Expertise: 10+ years serving Fortune 500 automotive suppliers.

• Competitive Pricing: Lean manufacturing principles keep costs 15–20% below competitors without compromising quality.

• Fast Turnaround: 4–6 weeks for standard molds, 50% faster than industry averages.

In a world where precision dictates profitability, PFT stands as a beacon of reliability. Whether you’re scaling up automotive production or innovating in injection molding, our blend of technology, craftsmanship, and customer-first values ensures your success.

Ready to elevate your manufacturing? Contact us today to discuss your project—no upfront fees, just results that speak for themselves.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.