High-Precision CNC Marine Components for Shipbuilding & Offshore Applications

Why Precision Matters in Marine Engineering?

Imagine a cargo ship battling fierce ocean waves or an offshore oil rig enduring decades of saltwater corrosion. Every component’s precision directly impacts safety and performance. At PFT, we specialize in manufacturing high-precision CNC marine components that meet the rigorous demands of shipbuilding and offshore industries.

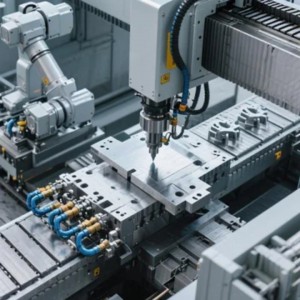

Advanced Technology, Unmatched Precision

Our factory is equipped with state-of-the-art 5-axis CNC machines capable of producing complex geometries with tolerances as tight as ±0.005mm . From propeller shafts to hydraulic valve blocks, our technology ensures:

l Durability: Components made from corrosion-resistant alloys like duplex stainless steel and titanium.

l Efficiency: Reduced material waste through optimized cutting paths, lowering costs by 15–20% .

l Versatility: Capable of processing metals, composites, and engineering plastics for diverse applications.

Rigorous Quality Control: From Raw Material to Final Product

Quality isn’t an accident—it’s engineered. Our three-stage inspection system guarantees reliability:

- Material Certification: Only ISO-certified suppliers are selected.

- In-Process Monitoring: Real-time sensors detect deviations during machining.

- Final Testing: Hydrostatic pressure tests and 3D scanning for 100% compliance with ABS and DNV standards .

Custom Solutions for Unique Challenges

No two marine projects are identical. Our engineers work closely with clients to develop tailored solutions, such as:

- Custom Flange Designs for high-pressure pipeline systems.

- Lightweight Aluminum Alloy Brackets for offshore wind turbines.

- Emergency Repair Services: 72-hour turnaround for critical replacements.

Sustainability Meets Innovation

As the industry shifts toward greener practices, we lead with:

- Energy-Efficient Machining: Solar-powered facilities reduce carbon footprint.

- Recycling Programs: 98% of metal scraps are recycled.

- Bio-Friendly Coatings: Non-toxic anti-fouling treatments for marine ecosystems.

Global Trust, Local Support

With over 200 clients across 30 countries, our commitment extends beyond delivery:

- 24/7 Technical Support: Multilingual engineers on standby.

- Warranty & Maintenance: 5-year warranty with annual maintenance packages.

- Transparent Communication: Real-time production updates via our client portal.

Your Next Step Toward Reliable Marine Components

Don’t compromise on quality. Contact PFT today to discuss your project needs. Let our expertise in CNC marine components become your competitive edge.

Why Choose Us?

✅ 20+ years of industry expertise

✅ ISO 9001 & 14001 certified

✅ 98% on-time delivery rate

✅ 24/7 customer service

PFT– Where Precision Meets the Sea.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.