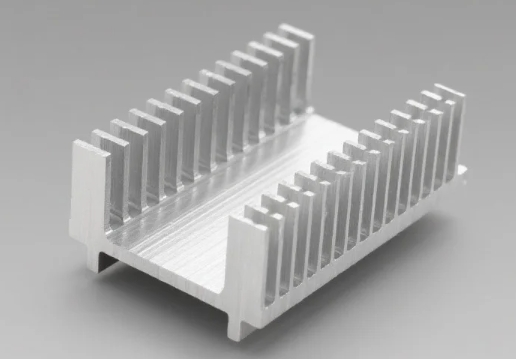

High-Precision Aluminum Heat Sinks for Semiconductor Thermal Management Solutions

In today’s era of high-performance electronics, effective thermal management is non-negotiable. At PFT, we specialize in manufacturing high-precision aluminum heat sinks that deliver unmatched cooling efficiency for semiconductor applications. With over 20+ years of expertise, we’ve become a trusted partner for industries demanding reliability, durability, and innovation in thermal solutions.

Why Choose Our Aluminum Heat Sinks?

1. Advanced Manufacturing Capabilities

Our facility houses state-of-the-art CNC machining centers and automated extrusion lines, enabling micron-level precision in heat sink production. Unlike conventional methods, our proprietary multi-stage surface treatment (anodizing, powder coating) ensures optimal thermal conductivity (up to 201 W/m·K) while enhancing corrosion resistance for harsh environments .

2. Customized Designs for Diverse Needs

From compact chips in IoT devices to large-scale server racks, our portfolio includes:

• Extruded profiles (6061/6063 aluminum alloys)

• Stamped fin arrays for high-density cooling

• Liquid-cooled hybrid solutions

• Custom geometries for AI processors and 5G infrastructure

3. Rigorous Quality Control

Every batch undergoes a 12-step inspection protocol:

• 3D laser scanning for dimensional accuracy (±0.05mm tolerance)

• Thermal simulation testing under real-world load conditions

• Salt spray testing (ASTM B117) for surface durability

This ensures compliance with ISO 9001 and IATF 16949 standards, minimizing failure rates to <0.1% .

4. End-to-End Support

We don’t just ship products—we partner for success:

• Free thermal design consultations with our engineering team

• 5-year warranty on all standard models

• Emergency replacement within 72 hours globally

Solving Real-World Thermal Challenges

Semiconductor manufacturers face critical pain points:

|

Challenge |

Our Solution |

|

Heat accumulation in tight spaces |

Ultra-thin (1.2mm) fin arrays with 30% higher surface area |

|

Vibration-induced performance drop |

Interlocking fin design with shock-absorbing baseplates |

|

High-volume production delays |

Just-in-time delivery with MOQs as low as 500 units |

Recent case studies show our heat sinks reduced junction temperatures by 22°C in EV power modules, extending component lifespan by 40% .

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.