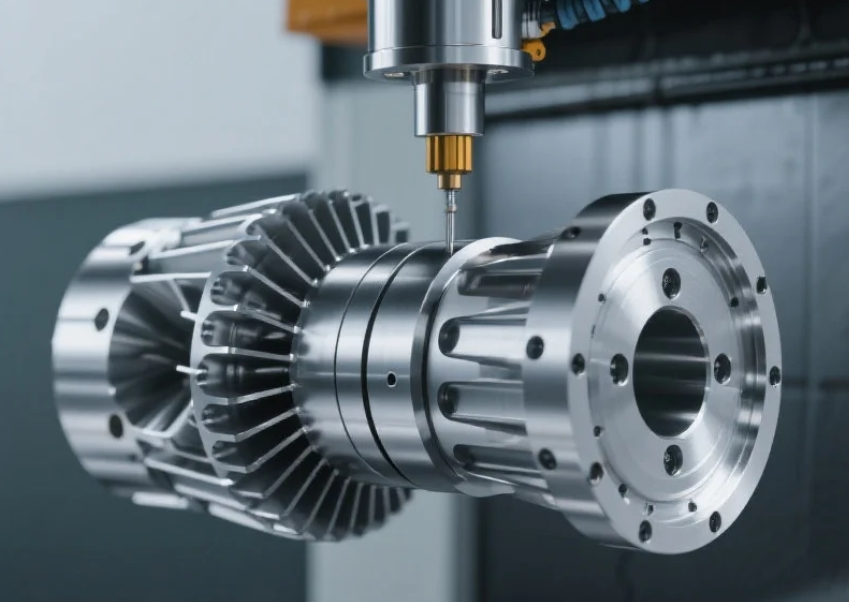

High-Precision 5-Axis CNC Machined Aircraft Engine Components

In the aerospace industry, precision isn’t just a requirement—it’s a lifeline. Aircraft engine components demand micron-level accuracy, complex geometries, and materials capable of withstanding extreme conditions. At PFT, we specialize in high-precision 5-axis CNC machining to deliver components that meet these rigorous standards, ensuring safety, performance, and reliability. Here’s why we’re the trusted partner for aerospace manufacturers worldwide.

1. Advanced Technology: 5-Axis CNC Machining Redefined

Our facility houses state-of-the-art 5-axis CNC machines capable of producing intricate turbine blades, engine casings, and structural airfoils with unparalleled precision. Unlike traditional 3-axis machines, our 5-axis systems rotate tools across multiple angles in a single setup, reducing errors and enabling complex geometries like curved airfoils and cooling channels . For example, turbine blades—critical for engine efficiency—are machined to tolerances as tight as ±25 microns, ensuring optimal aerodynamics and fuel efficiency .

To maintain consistency, our climate-controlled production halls (20°C) stabilize materials and tools, minimizing thermal expansion and ensuring dimensional stability during machining .

2. Unmatched Expertise: From Design to Delivery

Our team combines decades of aerospace manufacturing experience with cutting-edge software for toolpath optimization and isotropic cutting algorithms. This approach reduces processing time by 30% while enhancing surface finish quality to 0.2 microns, critical for reducing aerodynamic friction and noise .

For complex components like engine mounts or wing spars, we employ layer-by-layer and equal-height cutting strategies, balancing precision with tool longevity. This ensures even the most challenging designs—such as titanium alloy parts requiring high strength and corrosion resistance—are executed flawlessly .

3. Rigorous Quality Control: Trust Built on Precision

Every component undergoes multi-stage inspections using high-precision 3D measuring machines and coordinate measuring systems (CMMs). We adhere to aerospace-grade certifications, with tolerances rigorously verified to meet ISO 9001 and AS9100 standards . For turbine blades, we implement sandblasting and non-destructive testing (NDT) to eliminate surface defects and ensure structural integrity under extreme temperatures .

4. Diverse Product Portfolio: Beyond Engines

While aircraft engine components are our specialty, our capabilities extend to:

●Turbine blades and vanes with intricate cooling channels .

●Lightweight structural parts (e.g., wing ribs, landing gear components) .

●Medical and automotive prototypes requiring complex geometries .

Our 24-tool automatic changers and high-speed spindles (up to 24,000 RPM) enable rapid transitions between projects, supporting both small-batch prototypes and large-scale production .

5. Customer-Centric Service: Partnership Beyond Production

We prioritize transparency and timely delivery. From initial design consultations to post-production support, our team provides real-time updates and collaborates closely with clients to refine specifications. Whether you need a single prototype or 10,000 units, we guarantee on-time delivery without compromising quality .

Why Choose Us?

●✅ 5-axis CNC technology for complex, high-tolerance parts.

●✅ ISO-certified quality control with micron-level precision.

●✅ Rapid prototyping and mass production capabilities.

●✅ Dedicated support from industry experts.

Ready to Elevate Your Aerospace Projects?

Contact PFT today to discuss your requirements. Let our expertise in 5-axis CNC machining transform your designs into high-performance reality.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.