Great Machining Parts Factory

Product Overview

How do you tell them apart? Is it just about who has the newest equipment or the lowest price?

Having been in this industry for years, I can tell you it's not. The real difference between an average shop and a top-tier partner often comes down to things you can't see in a promotional video. It's the stuff that happens around the machines that truly matters.

Let's break down what you should be looking for.

Here's a little secret. If you send a CAD file to a factory and get a automated quote back in minutes with zero questions, be cautious. That's a red flag.

A great partner will actually talk to you. They'll call or email with smart questions like:

● "Hey, can you tell us what this part actually does? Is it for a prototype, or a final product going into a tough environment?"

● "We noticed this tolerance is extremely tight. It's achievable, but it will cost more. Is that critical for the part's function, or can we loosen it a bit to save you money without any performance loss?"

● "Have you thought about using a different material? We've seen similar parts perform better with [Alternative Material]."

This conversation shows they're trying to understand your project, not just process an order. They're looking out for your budget and the success of your part from day one. That's a partner.

Sure, modern 3-axis, 5-axis, and Swiss-type CNC machines are fantastic. They're the backbone. But a machine is only as good as the person programming it.

The real magic is in the CAM programming. A seasoned programmer doesn't just tell the machine what to do; they figure out the smartest way to do it. They plan the toolpaths, select the right cutting speeds, and sequence the operations to get you the best possible finish in the shortest amount of time. This expertise can save you hours of machine time and a lot of money.

Look for a factory that talks about their team's experience and skill. That's a much better sign than one that just lists their equipment.

Any shop can get lucky and make one good part. A true factory partner delivers a batch of 10,000 parts where every single one is identical and perfect. How? Through a rock-solid Quality Control (QC) process.

This is absolutely critical. Don't be shy to ask about it. You want to hear them mention:

● First Article Inspection (FAI): A complete, documented check of the very first part against every single spec on your drawing.

● In-Process Checks: Their machinists aren't just loading material; they're regularly measuring parts during the run to catch any tiny deviations early.

● Real Metrology Tools: Using equipment like CMMs (Coordinate Measuring Machines) and digital calipers to provide you with actual inspection reports.

If they can't clearly explain their QC process, it probably means it's not a priority. And that's a risk you don't want to take.

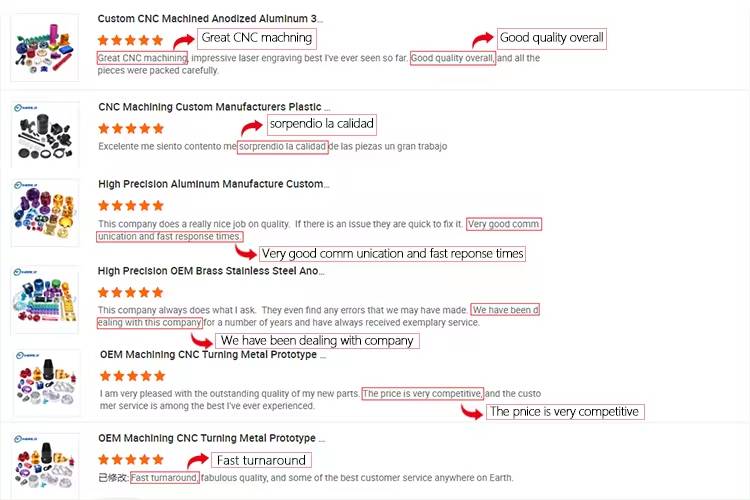

Choosing a machining parts factory is a big deal. You're trusting them with a piece of your project. It's worth looking beyond the price tag.

Find a partner who communicates well, has skilled people, and can prove their quality. Your goal isn't just to get a part made. It's to get the right part, made perfectly, on time, and without any headaches.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

● ±0.005" (±0.127 mm) standard

●Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.