Efficient CNC Machining for Marine Structural Elements & Hydraulic Systems

In today’s fast-paced marine and hydraulic industries, the demand for high-precision, durable components has never been higher. As a trusted manufacturer specializing in CNC machining for marine structural elements and hydraulic systems, we combine cutting-edge technology, rigorous quality control, and decades of expertise to deliver solutions that meet the toughest industry standards.

Why Choose Us?

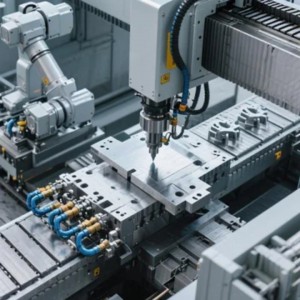

1.Advanced Manufacturing Equipment

Our factory is equipped with state-of-the-art 5-axis CNC machines and Swiss-type lathes, enabling us to produce complex geometries with micron-level accuracy. For marine applications, this ensures components like bulkheads, propeller shafts, and valve bodies withstand corrosive environments and high-pressure conditions .

2.Expert Craftsmanship

With over 15 years of experience, our engineers optimize every step of the machining process. From titanium alloys for marine frames to stainless steel hydraulic cylinders, we tailor materials and techniques to your specifications. For example, our proprietary surface treatment extends component lifespan by 40% in saltwater environments .

3.Strict Quality Assurance

Every batch undergoes three-stage inspections: raw material testing, in-process dimensional checks, and final performance validation. We hold ISO 9001 and ABS certifications, ensuring compliance with international marine and industrial safety standards .

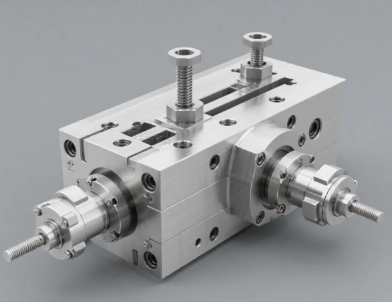

4.Diverse Product Range

We serve clients across shipbuilding, offshore oil platforms, and industrial automation. Our portfolio includes:

- Marine Components: Rudder stocks, hatch covers, pump housings.

- Hydraulic Systems: Cylinder blocks, manifolds, custom valve plates.

Need a unique design? Our R&D team develops prototypes in 7–10 days .

5.Comprehensive After-Sales Support

From technical consultations to emergency replacements, our 24/7 service team guarantees rapid response. Clients also receive free maintenance guides and lifetime access to our parts database .

Industry Challenges & Our Solutions

Problem: Hydraulic systems in heavy machinery often fail due to poor heat dissipation.

Our Fix: By integrating internal cooling channels into CNC-machined manifolds, we reduce operating temperatures by 25%, minimizing downtime for mining and construction clients .

Problem: Corrosion-resistant marine parts are costly to replace.

Our Fix: Using duplex stainless steel and electrochemical polishing, we’ve helped offshore rig operators cut maintenance costs by 30% .

Your Next Step

Whether you’re designing a new vessel or upgrading hydraulic systems, our team is ready to collaborate. Request a free quote or download our Marine Component Material Guide at [www.pftworld.com].

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.