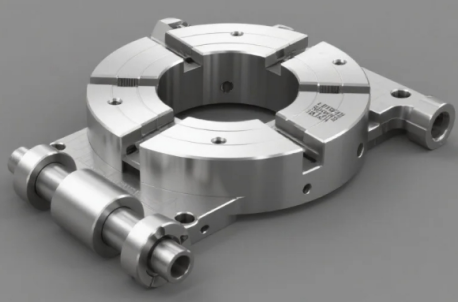

Durable CNC Milling & Turning Parts for Heavy-Duty Manufacturing Equipment

When reliability matters most in heavy-duty manufacturing, every component must withstand extreme conditions. At PFT, we specialize in producing high-performance CNC milling and turning parts engineered for durability, precision, and longevity. With over 20+ years of expertise, we’ve become the trusted partner for industries ranging from aerospace to construction.

Why Choose Us? 3 Pillars of Excellence

1.Advanced Manufacturing Capabilities

Our factory houses state-of-the-art CNC machines (3-axis to 5-axis) capable of handling complex geometries and tight tolerances (±0.005mm). Whether you need custom CNC turned parts for hydraulic systems or large-scale milling components for mining equipment, our technology ensures:

- Material versatility: Machining stainless steel, titanium, Inconel®, and engineering-grade plastics.

- Scalability: Prototyping to bulk production (up to [X units/month]).

- Speed: Fast turnaround times without compromising quality.

2.Rigorous Quality Assurance

Quality isn’t an afterthought—it’s embedded in our process:

- ISO 9001:2015-certified workflows with in-process inspections using CMM and optical comparators.

- Traceability: Full documentation for every batch, including material certifications and test reports.

- Post-processing excellence: Surface finishes from Ra 0.8μm mirror polish to protective coatings like anodizing or powder coating.

3.End-to-End Customer Support

From design optimization to after-sales service, we simplify your supply chain:

- Free DFM (Design for Manufacturability) analysis to reduce costs and lead times.

- 24/7 project management: Dedicated engineers track your order in real time.

- Warranty & spare parts: 5-year warranty on critical components and rapid replacement services.

Industries We Serve

Our CNC-machined parts power mission-critical applications:

- Construction & Mining: Gearboxes, hydraulic valve bodies, and wear-resistant bushings.

- Energy Sector: Turbine blades, heat exchanger components.

- Transportation: Precision engine parts and suspension systems.

Case Study: Solving a Client’s Challenge

A leading heavy machinery manufacturer faced frequent downtime due to subpar milling parts. By switching to our hardened steel CNC-machined rollers (HRC 60+), they achieved:

- 40% longer service life under abrasive conditions.

- 15% cost savings through optimized material usage.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.