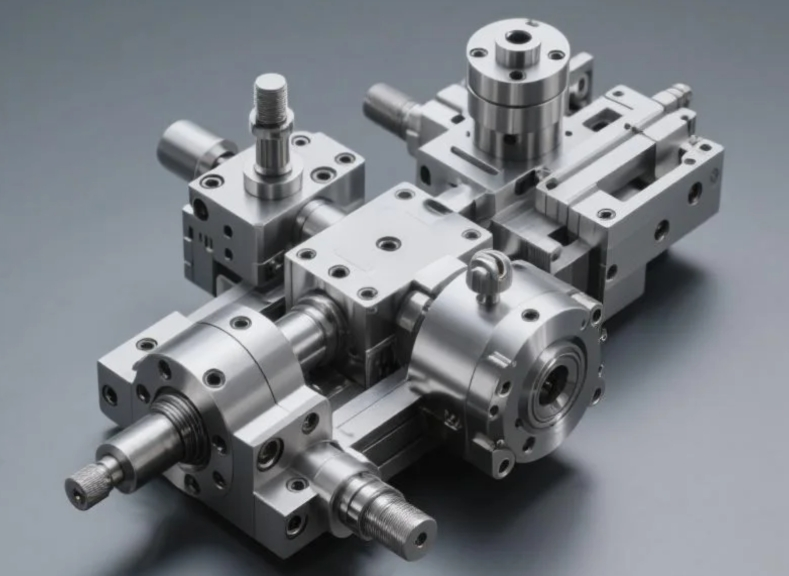

Durable CNC Metal Parts with Servo Control for Automation Machinery

In today’s fast-paced industrial landscape, automation machinery demands components that combine durability, precision, and adaptability. As a leading manufacturer specializing in CNC metal parts with servo control, we leverage cutting-edge technology and decades of expertise to deliver solutions that power automation systems worldwide.

1. Advanced Manufacturing Capabilities: Where Technology Meets Precision

Our factory houses state-of-the-art CNC machining centers equipped with servo-controlled systems, ensuring micron-level accuracy for complex geometries. From aluminum alloys to stainless steel, our machines handle diverse materials while maintaining ±0.005mm tolerances—critical for high-speed automation applications.

●Why it matters: Servo control enhances motion stability, reducing vibration and wear in machinery .

●Key feature: Multi-axis synchronization for intricate components like robotic arms and conveyor systems.

2. Craftsmanship Rooted in Innovation

Beyond hardware, our engineers optimize every process—from CAD/CAM programming to post-processing. We adopt adaptive machining strategies to minimize material waste and extend tool life, aligning with sustainable manufacturing trends.

●Case in point: A recent project involving aerospace actuators required 15+ iterative prototypes; our team delivered a 30% faster cycle time through toolpath optimization .

3. Rigorous Quality Control: Built to Last

Quality isn’t an afterthought—it’s embedded in our DNA. Our ISO 9001-certified system includes:

●In-line inspection: Real-time CMM (Coordinate Measuring Machine) checks during production.

●Material traceability: Full documentation from raw material batches to final shipments.

●Stress testing: Simulating 10,000+ operational cycles to validate longevity .

4. Versatile Solutions for Cross-Industry Demands

Whether you’re in automotive, medical devices, or industrial robotics, our product portfolio adapts to your needs:

●Core offerings: Gears, housings, sensor mounts, and custom hydraulic components.

●Specialized services: Low-volume prototyping to large-scale production with fast turnaround times (as quick as 5 days).

●Industry-specific expertise: For example, medical-grade parts compliant with ISO 13485 standards .

5. Beyond Delivery: Partnership-Centric Support

We believe in building relationships, not just transactions. Our 24/7 technical support and warranty programs ensure seamless integration of parts into your systems.

●Added value: Free design consultations to optimize your components for cost-efficiency.

●Global reach: Warehouses in the US, EU, and Asia enable timely logistics .

Case Study: Elevating Efficiency for a Packaging Machinery Client

A client sought servo-controlled shafts to reduce downtime in their bottling line. By redesigning the gear profile and implementing surface hardening, we achieved:

●40% longer service life.

●15% energy savings through reduced friction.

●Full ROI within 8 months .

FAQs: Addressing Your Concerns

Q: Can you handle ultra-thin wall machining?

A: Yes! Our thin-wall machining expertise supports parts as thin as 0.3mm without deformation.

Q: What file formats do you accept for custom orders?

A: STEP, IGES, or SolidWorks files—we’re flexible!

Q: How do you ensure confidentiality?

A: All designs are protected by NDAs and encrypted servers.

Why Choose Us?

✅ 20+ years in precision manufacturing.

✅ 98% on-time delivery rate.

✅ 50+ skilled engineers on-site.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.