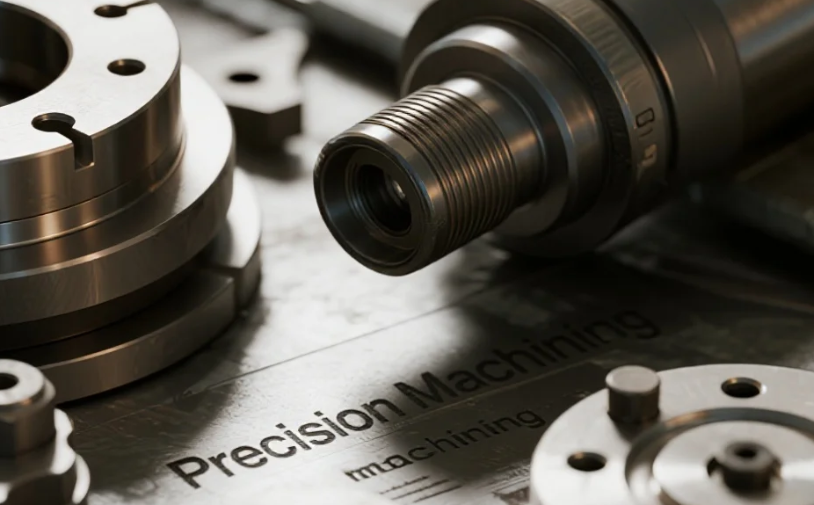

Delrin Precision Machining for Wear-Resistant Bushings

Professional Manufacturing, Quality Choice

Finding reliable, long-lasting wear-resistant bushings shouldn’t be a constant headache. If you’re dealing with premature wear, excessive noise, or unplanned downtime from failing components, the solution often lies in the material and the machining.

That’s where Delrin precision machining shines—and it’s our factory’s specialty.

Why Delrin (POM-H) for Bushings?

Delrin homopolymer acetal is a superstar in engineering thermoplastics, especially for wear-resistant bushings. Think about demanding applications:

-

Conveyor systems

-

Agricultural machinery

-

Automotive components

-

Industrial automation

Key Benefits of Delrin Bushings:

✔ Exceptional Wear Resistance – Minimizes friction and withstands abrasion far better than alternatives, extending bushing life.

✔ Low Friction & Self-Lubricating – Reduces the need for external lubricants, simplifying maintenance.

✔ High Strength & Stiffness – Maintains dimensional stability under load, crucial for precision applications.

✔ Excellent Chemical Resistance – Holds up against fuels, solvents, and harsh chemicals.

✔ Low Moisture Absorption – Performs consistently in humid environments without swelling.

But here’s the catch: Unlocking Delrin’s full potential requires expert precision machining.

Our Factory: Where Precision Meets Performance

We don’t just make bushings—we engineer durable, precision solutions. Here’s what sets us apart:

✔ Advanced CNC Machining Capabilities

-

Modern CNC turning & milling centers calibrated for Delrin.

-

Tight tolerances (often within ±0.001″) for perfect fit and performance.

✔ Material Expertise & Selection

-

Not all Delrin is the same—we choose the right grade for your needs:

-

FDA-compliant

-

Glass-filled for extra stiffness

-

Bearing-grade for ultimate wear resistance

-

✔ Surface Finish Perfection

-

Smooth finishes reduce break-in time and maximize lifespan.

✔ Rigorous Quality Control

-

Precision gauges, CMM inspection, and strict protocols ensure every bushing meets specs.

✔ Solving Complex Bushing Challenges

-

Intricate geometries? Custom flanges, grooves, or lubrication channels?

-

Our engineering team translates your needs into high-performance solutions.

✔ Scalability & Flexibility

-

Prototypes or high-volume production? We adapt to your needs.

-

Low minimum order quantities available.

✔ Dedicated Support, From Quote to Delivery

-

Expert guidance, clear communication, and seamless logistics.

-

We stand behind our products long after delivery.

Beyond Standard: Your Custom Wear Solution

While we excel at standard bushings, our true strength is customization.

Tell us about your application:

-

Loads & speeds

-

Operating temperatures

-

Mating materials

-

Environmental factors

We’ll recommend:

✅ Optimal Delrin grade

✅ Ideal wall thickness

✅ Lubrication strategy (if needed)

✅ Design enhancements for maximum longevity