Customized CNC Solutions for High-Tolerance Optics & Precision Instruments

Imagine you’re designing a satellite lens or a surgical laser component. You need tolerances under ±1.5µm, exotic materials like Zerodur®, and a supplier who won’t force you to choose between speed and precision. At PFT, we get it. That’s why our custom CNC machining for high-tolerance optics isn’t just about cutting metal—it’s about enabling breakthroughs .

Why Precision Isn’t Optional in Optics & Instruments

In aerospace, medical tech, or semiconductor manufacturing, sub-micron inaccuracies cause system failures. A misaligned mirror in a space telescope or a flawed lens in an endoscope can cost millions. Our clients demand:

• Nanometer-level accuracy for chip fabrication optics

• Non-contact measurement to prevent delicate surface damage

• Custom geometries for bespoke R&D projects

That’s where our solutions shine.

How We Deliver: Your Factory’s Core Strengths

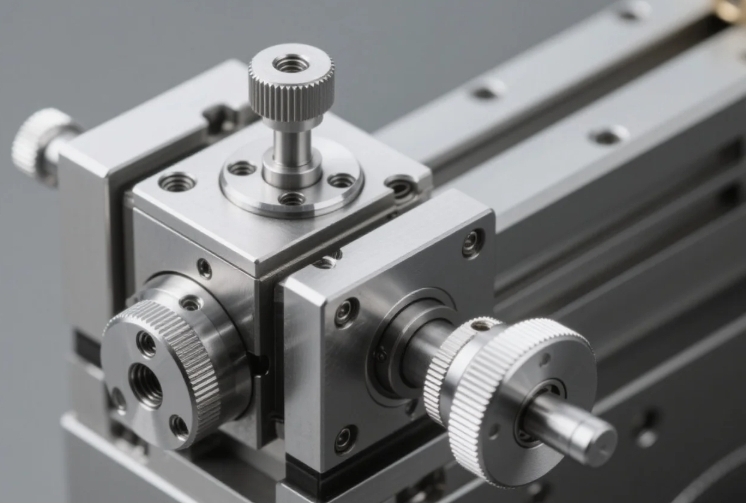

1. Advanced Equipment Built for Microscopic Precision

Our workshop runs 5-axis CNC machining centers with liquid-cooled spindles (±0.1°C thermal control) to eliminate tool drift during 48-hour cuts . For ultra-fine optics, we deploy:

• Deterministic polishing systems for surface roughness < 5Å

• 3D contour scanners to map lens curvature in real-time

• German-engineered OPTIMUM TC 62RC probes for tool calibration at ±0.5µm

2. Zero-Compromise Process Controls

We don’t just machine parts—we engineer reliability:

• AI-powered optical imaging: Detects subsurface flaws invisible to human inspectors .

• SPC (Statistical Process Control): Every batch generates automated reports tracking 65+ parameters (e.g., flatness, coaxiality) .

• Material science rigor: From titanium alloys to CVD silicon carbide, we’ve mastered stress-relieving heat treatments to prevent post-machining distortion .

3. Quality Control That Exceeds ISO 9001

Your surgical laser or satellite sensor deserves traceability down to the raw material lot:

• CMM + laser interferometry: Validates dimensions to ±0.8µm .

• Cleanroom assembly: Class 1000 environments for contamination-sensitive optics .

• Compliance documentation: Full GD&T reports, material certs, and 3D scan archives .

4. One-Stop Capabilities: From Prototypes to Volume Production

Whether you need 10 custom collimators or 10,000 precision instrument housings, our flexible cells handle:

• Optical components: Aspheric lenses, mirror substrates, prism assemblies

• Precision mechanical parts: Sensor mounts, actuator housings, micro-fluidic devices

• Materials mastery: Aluminum, brass, Invar®, fused silica, PEEK

5. After-Sales: Partnership Beyond Delivery

A cracked coating or an unexpected tolerance shift? Our support includes:

• 24/7 technical hotline with on-call engineers

• Free recalibration for legacy parts (up to 5 years post-delivery)

• Rapid-response prototyping: 72-hour turnaround for design adjustments

• Aerospace Client: Reduced satellite mirror alignment errors by 90% using our high-precision CNC optical grinding for SiC substrates. Result: 20% lighter payload, mission lifespan extended.

• Medical OEM: Eliminated post-sterilization distortion in endoscope barrels via our stress-relieved titanium machining. Result: 0.02% field failure rate.

Real-World Impact: Case Snapshots

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.