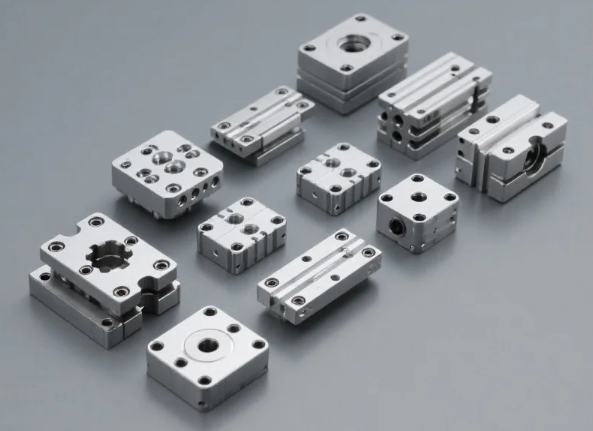

Custom CNC Milling Parts for Robotic Automation Systems

In today’s rapidly evolving industrial landscape, robotic automation systems are revolutionizing production efficiency and precision. For these systems to perform flawlessly, every component must meet the highest standards of accuracy and durability. As a trusted manufacturer specializing in Custom CNC Milling Parts for Robotic Automation Systems, we combine cutting-edge technology with decades of expertise to deliver solutions that empower innovation.

Why Choose Us?

1.Advanced Equipment & Multi-Axis Capabilities

Our factory houses 110+ CNC milling machines, including 3-, 4-, and 5-axis machining centers . This allows us to handle complex geometries—from intricate robotic end-effectors to high-precision storage units—with tolerances as tight as ±0.01mm . Whether it’s aluminum, stainless steel, titanium, or engineering plastics, our machines adapt seamlessly to diverse materials .

2.Quality Control That Exceeds Standards

Every part undergoes rigorous inspections using tools like 3D CMM scanners and spectrometers to ensure compliance with ISO 9001:2015 and industry-specific certifications . Our “zero defect” philosophy means even minor deviations are corrected before shipment, guaranteeing reliability in mission-critical applications .

3.Material Versatility & Surface Finishing Expertise

We work with over 15 metal alloys and 10+ engineering plastics, including aerospace-grade aluminum (7075-T6) and corrosion-resistant stainless steel (316L) . Post-machining treatments like anodizing, chrome plating, and sandblasting enhance both functionality and aesthetics, tailored to your robotic system’s environment

4.Rapid Turnaround, Scalable Production

Need prototypes or bulk orders? Our agile workflow ensures 5-15 workday delivery for small batches and seamless scaling for large volumes . With 24/7 engineering support, design optimizations are communicated in real-time to avoid delays .

Applications in Robotic Automatio

Our CNC-milled parts are integral to industries where precision is non-negotiable:

●Automotive: Custom transmission components and lightweight structural parts .

●Medical: Sterile surgical tool housings and implant prototypes .

●Electronics: Heat sinks and miniature connectors with EMI shielding .

●Aerospace: High-strength titanium brackets and sensor mounts .

For example, a recent project involved machining aluminum robotic arms for an automotive assembly line. By optimizing tool paths and material selection, we reduced weight by 20% while maintaining structural integrity—resulting in faster, energy-efficient operations .

End-to-End Service, From Concept to After-Sales

●Design Collaboration: Share your sketches or CAD files, and our engineers will refine them for manufacturability (DFM reports provided) .

●NDA Protection: Your intellectual property is safeguarded at every step .

●Global Logistics: We partner with DHL, FedEx, and sea freight providers for cost-effective shipping to the US, Europe, and beyond .

●Lifetime Support: Even post-delivery, our team troubleshoots wear-and-tear issues and offers reprocessing solutions .

Client Success Stories

●A medical device startup needed 500 PEEK surgical grippers with a 0.005mm surface finish. We delivered within 10 days, enabling their product launch ahead of schedule .

●An aerospace manufacturer praised our titanium drone mounts for surviving extreme vibration tests, calling it “a partnership that redefined precision” .

Let’s Build the Future of Automation Together

In robotics, every micron matters. With our blend of technology, transparency, and customer-centricity, we’re here to elevate your automation systems.

Contact us today for a free quote and see why global leaders trust us as their CNC milling partner.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.