Custom CNC Machined Ship Propellers with Tight Tolerances & Durability

In the demanding marine industry, ship propellers are the unsung heroes that ensure smooth navigation and fuel efficiency. At PFT, we specialize in crafting custom CNC machined ship propellers that meet the highest standards of precision, durability, and performance. With over 20+ of expertise, we’ve become a trusted partner for shipbuilders worldwide, delivering solutions that exceed expectations.

Why Choose Us? Advanced Technology Meets Expertise

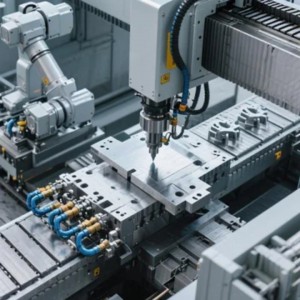

1.State-of-the-Art CNC Machining

Our factory is equipped with 7-axis 5-linkage CNC machines (developed through a decade of R&D), capable of handling propellers up to 7.2 meters in diameter and 160,000 kg in weight . This technology ensures S-class precision (the highest industry standard) and eliminates the need for multiple setups, boosting efficiency by 300% compared to traditional methods.

2.Superior Materials & Craftsmanship

We use corrosion-resistant alloys like nickel-aluminum bronze and stainless steel, rigorously tested for fatigue resistance and seawater compatibility . Each blade is individually forged, CNC-machined to ±0.01mm tolerances, and polished to reduce cavitation and noise—critical for luxury cruises and naval vessels .

3.End-to-End Quality Control

From material sourcing to final inspection, our ISO-certified process includes:

- 3D scanning for dimensional accuracy.

- Non-destructive testing (NDT) for internal defects.

- Hydrodynamic simulations to optimize thrust efficiency.

4.Custom Solutions for Every Need

Whether it’s a small fishing boat propeller or a mega-container ship component, we tailor designs to your vessel’s specifications. Recent projects include propellers for Italian luxury cruise lines and offshore drilling rigs, all meeting ABS, DNV, and Lloyd’s Register certifications .

Beyond Manufacturing: Services That Add Value

- Fast Turnaround: Leverage our just-in-time production model for urgent orders.

- Global Support: Our engineers provide 24/7 technical assistance, including installation guidance and maintenance tips.

- Sustainability Focus: CNC machining minimizes material waste by 30%, aligning with eco-friendly shipbuilding trends .

Ready to Navigate Success?

Explore our portfolio at [www.pftworld.com] or contact us at [alan@pftworld.com]. Let’s engineer propellers that propel your projects forward.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.