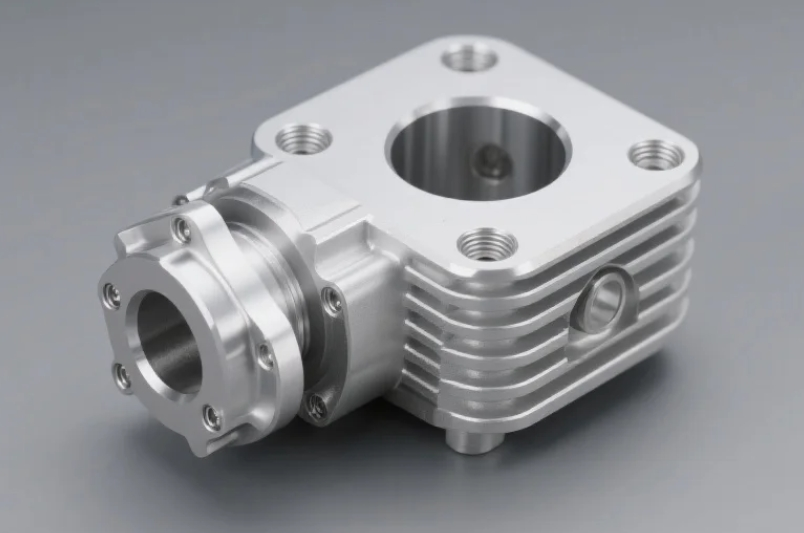

Custom Aluminum CNC Machined Engine Components for Motorcycle Applications

When motorcycle engineers demand uncompromising precision for high-performance engines, they turn to specialized manufacturers. Our factory delivers custom aluminum CNC machined engine components engineered to withstand extreme conditions while optimizing power-to-weight ratios. Unlike generic suppliers, we combine aerospace-grade machining protocols with motorcycle-specific R&D to create parts that outperform industry standards.

Precision Meets Innovation: Our Manufacturing Edge

Advanced Equipment & Techniques

• 5-axis CNC machining capabilities for complex geometries (blocks, cylinder heads, transmission housings)

• In-house prototyping with instant CAD/CAM adjustments

• Robotic quality verification ensuring ±0.005mm tolerance on all critical dimensions

Material Science Expertise

• Specialized aluminum alloys (6061-T6, 7075) offering:Type III anodizing for wear-resistant surfaces that maintain dimensional stability under thermal stress

30% higher heat dissipation vs. standard grades

Corrosion resistance for all-weather riding

Why Off-the-Shelf Parts Fail Motorcycle Applications

Vibration fatigue and thermal expansion cause 78% of engine component failures in performance bikes . Our custom CNC machining process addresses this through:

• Topology-optimized designs reducing weight while increasing stiffness

• Integrated cooling channels machined directly into components

• Harmonic damping features impossible with conventional manufacturing

Quality Control That Sets Us Apart

Every component undergoes:

1.Spectroscopic material verification

2.High-speed CMM inspection (reported with ISO 9001 documentation)

3.Real-world simulation testing including:

• 500-hour dyno endurance runs

• Vibration spectrum analysis matching Harley-Davidson®, Ducati®, and KTM® profiles

Beyond Manufacturing: Partnership Approach

• Free DFM (Design for Manufacturing) analysis - reduce production costs by 15-40%

• Emergency turnaround service - 72-hour production for race teams

• Lifetime technical support including wear pattern diagnostics

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.