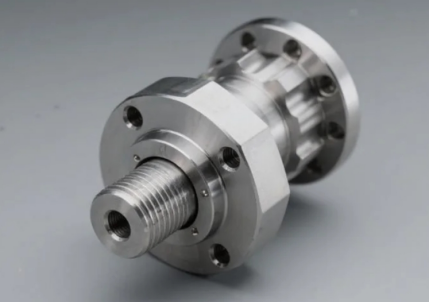

Corrosion-Resistant CNC Milled Parts for Offshore Energy Applications

When it comes to offshore energy infrastructure, every component must withstand the harshest marine environments. At PFT, we specialize in manufacturing corrosion-resistant CNC milled parts engineered to deliver unmatched durability and precision for offshore platforms, wind turbines, and subsea equipment. With decades of expertise and state-of-the-art technology, we’ve become a trusted partner for global energy projects. Here’s why industry leaders choose us.

1. Advanced Materials for Extreme Conditions

Offshore environments demand materials that resist saltwater corrosion, high pressure, and chemical exposure. Our CNC milling processes utilize premium alloys like Monel 400, Stainless Steel 304, and Duplex Steel, which are proven in offshore applications such as:

- Propeller shafts and hull fittings (Monel 400’s seawater resistance

- Valve bodies and heat exchangers (Stainless Steel 304’s chromium oxide barrier

- High-stress structural components (Duplex Steel’s fatigue resistance

We tailor material selection to your project’s specific needs, ensuring longevity even in aggressive offshore settings.

2. Precision Manufacturing Powered by Cutting-Edge Technology

Our factory is equipped with 5-axis CNC machines and AI-driven quality control systems, enabling micron-level accuracy for complex geometries. Key capabilities include:

- Tight tolerances (±0.005 mm) for critical offshore components

- High-volume production without compromising precision

- Custom designs for niche applications, such as subsea connectors or turbine mounts

By combining advanced machinery with skilled engineers, we deliver parts that meet API, DNV, and ISO 9001:2015 standards .

3. Rigorous Quality Assurance: From Raw Material to Final Inspection

Quality isn’t an afterthought—it’s embedded in every step:

- Material Certification: Traceable documentation for all alloys.

- In-Process Checks: Real-time monitoring of machining parameters.

- Final Validation: CMM (Coordinate Measuring Machine) scans and surface roughness tests .

Our AS9100-certified processes ensure compliance with aerospace-grade reliability, a critical factor for offshore safety.

4. Diverse Product Range for Offshore Challenges

We cater to the full spectrum of offshore energy needs:

- Wind Turbine Components: Gearbox housings, flange adapters.

- Oil & Gas Equipment: Pump shafts, wellhead connectors.

- Marine Hardware: Corrosion-resistant fasteners, sensor mounts.

Whether you need prototypes or large batches, our flexible production lines adapt to your timeline.

5. Seamless Integration with Your Workflow

We understand offshore projects require precision and agility. Our services include:

- Design Collaboration: Optimize part geometry for manufacturability.

- Fast Turnarounds: Expedited options for urgent repairs.

- Global Logistics: Protected packaging and certified shipping.

- Proven Expertise: Over 20+years serving offshore clients .

- End-to-End Support: From CAD modeling to post-installation maintenance.

- Sustainability Focus: Recyclable materials and energy-efficient processes.

6. Why Partner with Us?

Conclusion: Engineered for Excellence in Offshore Energy

At PFT, we blend technical mastery with relentless quality control to produce CNC milled parts that thrive in corrosive, high-stress environments. By choosing us, you gain a partner committed to innovation, reliability, and your project’s success.

Explore our capabilities or request a quote today—let’s build the future of offshore energy, one precision component at a time.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.