Complex Geometry Aerospace Structural Parts High-Efficiency Machining

Introduction: Meeting the Demands of Modern Aerospace Manufacturing

The aerospace industry demands components with complex geometries, ultra-high precision, and exceptional durability. As aircraft designs evolve toward lightweight, high-strength structures, manufacturers must balance efficiency with rigorous quality standards. How can factories meet these challenges while ensuring cost-effectiveness and timely delivery? The answer lies in advanced manufacturing capabilities, meticulous craftsmanship, and a customer-centric approach—qualities that define our factory’s commitment to excellence .

1. Advanced Manufacturing Capabilities: Precision at Scale

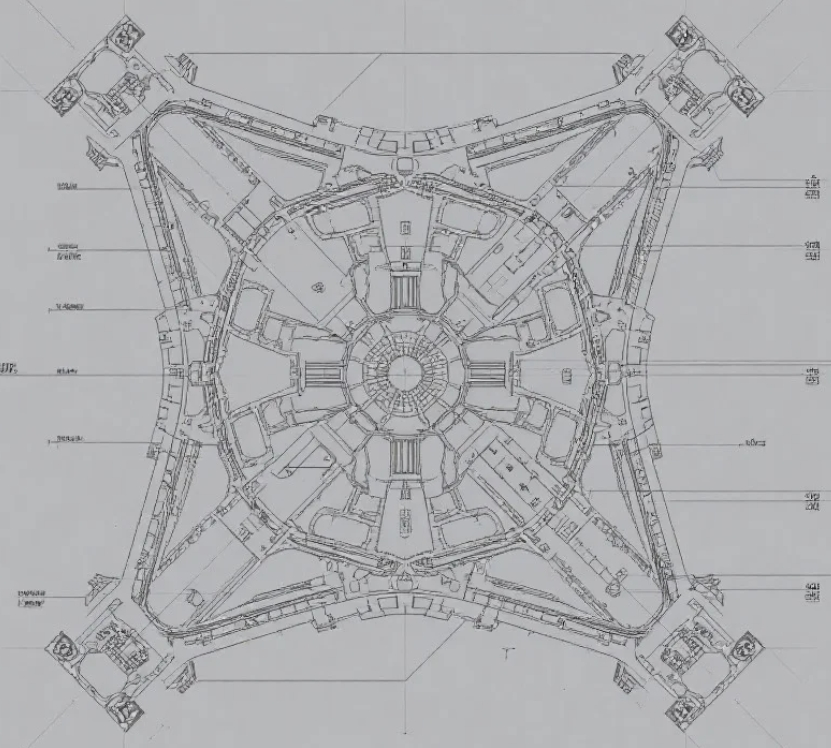

Our factory leverages state-of-the-art CNC machining centers, including 5-axis milling machines, to produce aerospace structural parts with intricate geometries. These machines enable:

●High-efficiency machining of titanium alloys, composites, and high-strength steels—materials critical for modern aircraft .

●Tolerance control within ±0.005 mm, ensuring components meet stringent aerospace specifications.

●Automated toolpath optimization to reduce material waste and shorten production cycles .

For example, our recent project involved machining a titanium alloy wing spar with internal honeycomb structures, achieving a 98% material utilization rate while maintaining AS9100 compliance.

2. Rigorous Quality Control: Trust Built on Consistency

Quality is non-negotiable in aerospace manufacturing. Our multi-stage inspection system includes:

●In-process CMM (Coordinate Measuring Machine) checks to monitor dimensional accuracy.

●Non-destructive testing (NDT) for detecting micro-cracks and material defects.

●Traceability protocols where each part is logged with a unique QR code, linking to its production history and test reports .

This system has earned us certifications like ISO 9001 and AS9100D, solidifying our reputation as a reliable partner for global aerospace OEMs.

3. Diverse Product Portfolio: Solutions for Every Challenge

From engine mounts to landing gear components, our factory specializes in:

●Complex thin-walled structures that reduce aircraft weight without compromising strength.

●Composite material machining, addressing the growing use of carbon fiber in next-gen aircraft.

●Rapid prototyping for R&D teams, accelerating time-to-market for new designs .

We also cater to niche applications, such as satellite components requiring radiation-resistant alloys, demonstrating our adaptability to diverse industry needs.

4. Customer-Centric Service: Beyond Delivery

Our commitment extends beyond production:

●Customized solutions: Collaborate with our engineers to optimize designs for manufacturability.

●Global logistics support: Streamlined shipping with real-time tracking for urgent orders.

●24/7 technical support: Dedicated teams assist with post-purchase queries, ensuring seamless integration of parts .

A recent client in the EU praised our ability to deliver 500+ turbine blades within 4 weeks, including surface treatment and documentation—proof of our end-to-end reliability.

Conclusion: Partner with a Leader in Aerospace Manufacturing

In an industry where precision and trust are paramount, our factory stands out through cutting-edge technology, uncompromising quality, and responsive service. Whether you’re developing next-gen aircraft or maintaining existing fleets, we provide solutions that elevate your projects.

Ready to discuss your needs? Contact our team today for a tailored quote or to explore our case studies.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.