CNC Turning Parts Manufacturer in China

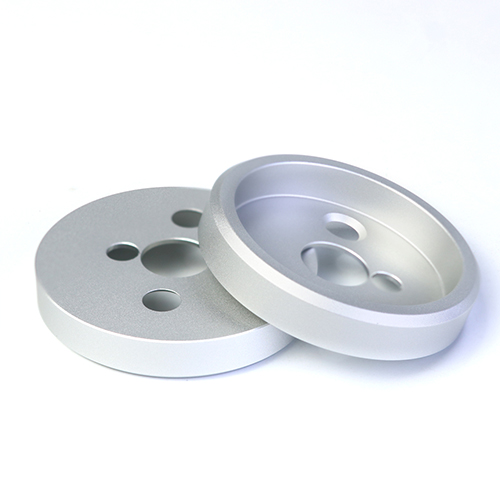

Product Overview

When it comes to manufacturing high-precision components, CNC turningis one of the most reliable and cost-effective methods. CNC turning allows manufacturers to produce parts with high accuracy and consistency, making it a preferred choice for industries such as aerospace, automotive, medical devices, and electronics.

Before we dive into why China is a leading player in CNC turning, let’s briefly explain what CNC turning is.

CNC turning is a machining process where a workpiece is rotated against a stationary cutting tool to remove material and shape it into the desired form. It’s typically used to create cylindrical parts or components with rotational symmetry, such as shafts, gears, bushings, and pulleys. The process involves precise control of the cutting tool’s movement along multiple axes, ensuring that each part meets tight tolerance specifications.

Some of the key advantages of CNC turning include:

● High precision: CNC turning provides exact dimensions and tight tolerances.

● Versatility: It can be used to produce a wide range of materials, from metals like stainless steel and aluminum to plastics and composites.

● Cost-efficiency: When mass-producing parts, CNC turning offers excellent repeatability and minimal material waste.

China has long been a leader in manufacturing, and when it comes to CNC turning parts, the country offers numerous advantages that make it an attractive option for businesses around the world. Here are some reasons why you should consider working with a CNC turning parts manufacturer in China:

1. Cost-Effectiveness

One of the most compelling reasons companies choose to work with manufacturers in China is cost savings. Labor costs in China are typically lower than in many Western countries, which directly translates to lower manufacturing costs for your CNC turning parts. Additionally, China’s advanced manufacturing infrastructure allows companies to produce parts at scale, further driving down the per-unit cost.

This cost advantage is particularly beneficial for businesses looking to outsource production without sacrificing quality. By leveraging China’s lower manufacturing costs, companies can maximize their profit margins or reinvest the savings into other areas of their business, such as product development or marketing.

2. Access to Advanced Technology and Expertise

China is home to a vast number of CNC machining facilities, many of which are equipped with state-of-the-art CNC turning machines and advanced production technologies. Manufacturers in China invest heavily in upgrading their machinery to stay competitive in the global market. This means that when you partner with a CNC turning parts manufacturer in China, you get access to the latest technology and high-end equipment without paying a premium.

Moreover, China’s manufacturing industry is known for its skilled workforce. Many CNC turning manufacturers employ highly trained engineers and technicians who are well-versed in the latest machining techniques, ensuring that your parts are produced to the highest standards. Whether you're creating simple or complex components, China-based manufacturers have the expertise to meet your needs.

3. High Volume and Scalability

China’s manufacturing infrastructure is designed to handle both small-batch and large-scale production runs efficiently. If your business needs to produce a large number of CNC turned parts for mass production, a Chinese manufacturer can scale production quickly while maintaining consistency and quality. This scalability is ideal for companies that are scaling up operations or need to meet fluctuating demand.

Many manufacturers in China also offer rapid prototyping services, allowing you to test your designs before committing to large-scale production. This is especially useful when you need to make adjustments or tweaks to your parts before finalizing the design.

4. Diverse Material Options

China’s CNC turning manufacturers are capable of working with a wide range of materials, from metals such as stainless steel, aluminum, and titanium to plastics and composite materials. This flexibility allows you to source parts made from the exact material that best suits your product’s requirements, whether it's for high-strength applications or lightweight designs.

The ability to work with various materials is especially important for industries like aerospace, medical devices, and automotive, where specific materials are required to meet safety, performance, and regulatory standards.

5. Quality Control and Certifications

While cost is often a driving factor for outsourcing production to China, quality is never compromised. Many CNC turning manufacturers in China adhere to international quality standards and are ISO-certified (e.g., ISO 9001:2015). This means they have implemented strict quality control processes to ensure that every part they produce meets your exact specifications.

Additionally, reputable manufacturers in China employ advanced inspection techniques, such as coordinate measuring machines (CMM), to verify the accuracy of every part before shipping. These measures ensure that the parts you receive are consistent, reliable, and free from defects, giving you peace of mind that your products will meet your standards.

6. Flexible Lead Times and Reliable Shipping

China’s extensive manufacturing network allows for quick turnaround times, even for complex parts. Whether you need a prototype or a high-volume production run, a reliable CNC turning parts manufacturer can provide fast lead times without compromising on quality.

Furthermore, China’s well-established global shipping infrastructure ensures that your parts can be delivered to your location efficiently. Shipping options range from air freight for faster delivery to sea freight for more cost-effective solutions. Most manufacturers also have experience navigating international customs, ensuring that your parts arrive on time and without hassle.

Not all CNC turning manufacturers in China are created equal. To ensure that you’re partnering with the right supplier, consider the following factors:

● Experience and Reputation: Look for manufacturers with a solid track record and experience in your industry. Check customer reviews, request case studies, or ask for referrals to gauge their capabilities.

● Certifications: Ensure that the manufacturer holds relevant certifications, such as ISO 9001, which indicate that they follow rigorous quality control processes.

● Communication and Support: Choose a manufacturer that offers clear communication and responsive customer support. This is crucial for addressing any issues that arise during the design or production process.

● Customization Capabilities: Make sure the manufacturer can meet your specific requirements, whether it’s for complex parts or specialized materials. Ask about their ability to handle custom designs and prototyping.

● Quality Assurance: Ask about their quality control processes and how they ensure parts meet your standards. Request inspection reports and test results if necessary.

Partnering with a CNC turning parts manufacturer in China offers numerous advantages, from cost savings to access to advanced technology and skilled labor. Whether you need high-precision parts for the automotive, aerospace, medical, or electronics industries, China’s robust manufacturing sector can deliver quality, reliability, and scalability to meet your business needs.

By carefully selecting a trusted manufacturer, you can streamline your production process, reduce costs, and ensure that your products are manufactured to the highest standards. If you're ready to take the next step in sourcing CNC turned parts, consider China as a top destination for your machining needs.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

● Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

● If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

● They even find any errors that we may have made.

● We have been dealing with this company for a number of years and have always recelved exemplary service.

● I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

● Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

●±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.