CNC milling service

Product Overview

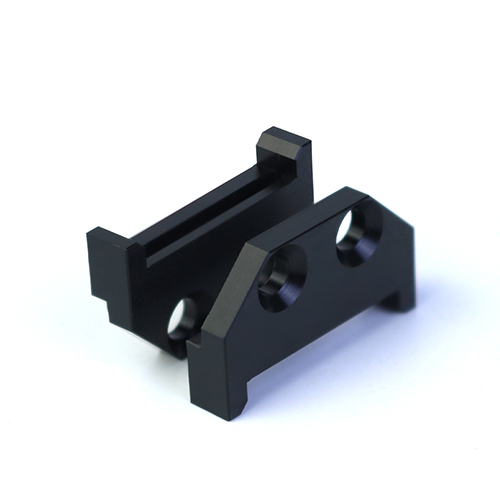

CNC Milling Service is a machining technology based on computer numerical control, which removes material from the workpiece through rotating and cutting tools to form parts with specific shapes and functions. The process usually uses CAD/CAM software to create a 2D or 3D model and convert it into a G-code program to be executed by a CNC milling machine.

●Control method: CNC milling is a machining process controlled by a computer. Unlike traditional milling, it does not require manual operation of rotating tools.

●Machining method: Using a rotating multi-point cutting tool, material is gradually removed to create custom designed parts or products.

●Precision and efficiency: CNC milling is able to achieve high precision and strict tolerance control. For example, multi-axis CNC machines can produce extremely complex shapes with tolerances up to ±0.004mm

● High precision and consistency: Due to computer control, CNC milling can achieve high precision and repeatability, ensuring consistent product quality.

● Reduced manual intervention: CNC milling can automatically complete the processing process, reducing dependence on manual labor and improving production efficiency.

● Flexibility: CNC milling can process a variety of materials, including plastics, metals, wood, ceramics and glass, and can quickly adapt to design changes.

● Environmental protection: CNC milling consumes less energy and has less impact on the environment than traditional processing methods.

CNC milling service is an advanced manufacturing technology that can provide customized precision processing solutions for various industries to meet different types of processing needs.

● Aerospace: used to manufacture complex aircraft components and engine parts.

● Automotive: used to produce precision parts such as engine blocks and gearbox housings

● Medical equipment: used to manufacture surgical instruments, prosthetic parts, etc.

● Electronics: used to manufacture small precision parts such as circuit boards and connectors.

● Mold manufacturing: used to manufacture injection molds, stamping molds, etc.

● Defense industry: used to manufacture precision parts in weapon systems.

● Food processing: used to manufacture parts for food processing equipment.

produce high-quality products in less time, enabling you to meet deadlines faster and increase customer loyalty.

A CNC router is a game-changer for factories looking to improve precision, efficiency, and product quality. Whether you’re in the woodworking, sign-making, or custom manufacturing industries, the CNC router offers the versatility and automation necessary to take your factory to the next level.

By investing in a CNC router, your factory can streamline operations, reduce costs, and unlock new opportunities for growth and innovation. If you want to stay competitive in today’s fast-paced manufacturing world, a CNC router is the key to achieving lasting success.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

If there is an issue they are quick to fix itVery good communication and fast responise times.This company always does what I ask.

They even find any errors that we may have made.

We have been dealing with this company for a number of years and have always recelved exemplary service.

I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

● ±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.

and engineers to quickly create prototypes from various materials and test their designs before mass production. CNC routers are ideal for prototyping because they can easily handle custom shapes and designs, speeding up the development process.