CNC Machining Parts Supplier

Product Overview

In today’s fast-paced manufacturingworld, precision, speed, and reliability are non-negotiable. Whether you're in aerospace, automotive, medical devices, or any other industry requiring highly accurate parts, CNC (Computer Numerical Control) machining has become the go-to solution. But here’s the catch—having access to state-of-the-art machinery is only half the battle. The other half lies in choosing the right CNC machining parts supplier.

Before diving into the supplier selection process, let’s quickly cover what CNC machining is. Simply put, CNC machining involves the use of computer-controlled machines to cut, mill, drill, or shape material into precise parts. These parts can be made from a wide range of materials, including metals, plastics, and composites, and are used in everything from engine components to intricate medical devices.

What makes CNC machining stand out is its ability to deliver precision and repeatability at scale, making it a preferred method for producing high-quality parts in industries where tolerance and performance matter.

A CNC machining parts supplier is more than just a company that manufactures your components. They’re your partner in ensuring that your parts meet the highest standards of quality, consistency, and performance. From sourcing raw materials to managing production timelines, the supplier plays a pivotal role in the success of your project.

But with so many CNC machining suppliers out there, how do you know which one is right for you? Let’s break it down.

1. Quality and Precision

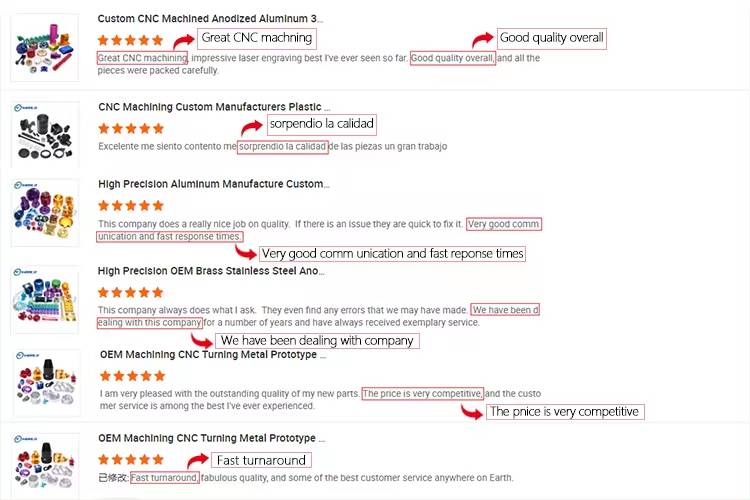

When it comes to CNC machining, quality is everything. A high-quality part can be the difference between a product that performs reliably and one that fails. The best suppliers will have rigorous quality control processes in place, using advanced measurement tools and techniques to ensure each part meets exact specifications.

Look for suppliers who provide clear documentation of their quality control practices, such as ISO 9001 certifications or other industry-standard accreditations. These certifications ensure that the supplier is committed to maintaining consistent quality.

2. Lead Time and Delivery Reliability

Speed matters, especially if you’re working on tight deadlines. A good CNC machining supplier understands the importance of timely delivery. They should have the ability to deliver parts within the agreed-upon timeframe, without compromising on quality.

Ask potential suppliers about their production schedules and their track record on meeting deadlines. A supplier who consistently delivers on time can help prevent costly delays in your own production process.

3. Material Expertise

CNC machining is versatile, but the material you choose plays a huge role in the final product’s performance. Whether you’re working with stainless steel, titanium, aluminum, or engineering plastics, your supplier should have experience working with a wide variety of materials.

Choosing a supplier with deep knowledge of material properties can help ensure that your parts are not only precision-engineered but also optimized for performance. Be sure to discuss your material needs upfront to ensure the supplier has the expertise to work with the specific materials required for your project.

4. Customization and Flexibility

Not every CNC machining project is straightforward. Sometimes, you need custom solutions for specialized parts or designs. The best suppliers offer flexibility and are willing to work with you to develop tailor-made solutions that meet your exact specifications.

Whether it’s custom tooling, unique geometries, or small batch runs, a responsive and adaptable supplier can save you time, money, and frustration. Look for a supplier who is willing to collaborate and provide design assistance when needed.

5. Cost-Effectiveness

While quality should always be the top priority, cost is an important consideration too. However, it’s important to avoid the temptation to choose the cheapest option. In the world of CNC machining, you get what you pay for. A supplier that offers rock-bottom prices may cut corners on quality or fail to deliver on time.

Instead, look for a supplier who offers competitive pricing while maintaining high standards of quality and service. A good supplier should be transparent about their pricing structure, offering clear and accurate quotes that reflect the complexity of the job.

6. Technical Support and Customer Service

Another important factor to consider is the level of technical support and customer service your supplier provides. CNC machining can be complex, and issues can arise at any stage of the process. Having a supplier who is responsive and willing to help solve problems can make a huge difference in keeping your project on track.

A good CNC supplier should be easy to communicate with, offering both pre-production and post-production support. Whether you need assistance with design tweaks or help troubleshooting a production issue, excellent customer service can ensure a smooth experience from start to finish.

Choosing the right CNC machining parts supplier is not just a business transaction, but a crucial decision that impacts your entire production process. By focusing on quality, reliability, flexibility, and customer service, you can partner with us to help you achieve your business goals.

Q:How fast can I receive a CNC prototype?

A:Lead times vary depending on part complexity, material availability, and finishing requirements, but generally:

● Simple prototypes: 1–3 business days

● Complex or multi-part projects: 5–10 business days

Expedited service is often available.

Q:What design files do I need to provide?

A:To get started, you should submit:

● 3D CAD files (preferably in STEP, IGES, or STL format)

● 2D drawings (PDF or DWG) if specific tolerances, threads, or surface finishes are required

Q:Can you handle tight tolerances?

A:Yes. CNC machining is ideal for achieving tight tolerances, typically within:

●±0.005" (±0.127 mm) standard

● Tighter tolerances available upon request (e.g., ±0.001" or better)

Q:Is CNC prototyping suitable for functional testing?

A:Yes. CNC prototypes are made from real engineering-grade materials, making them ideal for functional testing, fit checks, and mechanical evaluations.

Q:Do you offer low-volume production in addition to prototypes?

A:Yes. Many CNC services provide bridge production or low-volume manufacturing, ideal for quantities from 1 to several hundred units.

Q:Is my design confidential?

A:Yes. Reputable CNC prototype services always sign Non-Disclosure Agreements (NDAs) and treat your files and intellectual property with full confidentiality.