CNC Machining in China

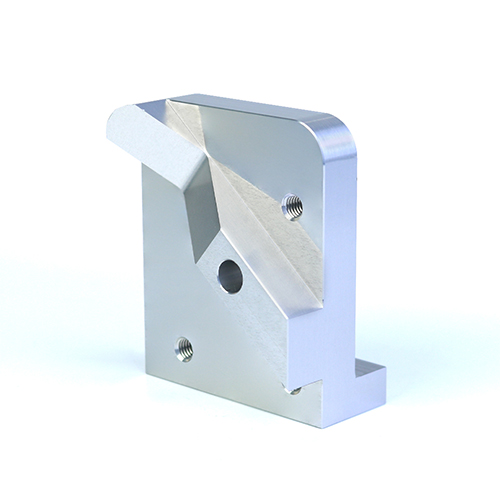

Product Overview

Hey there, curious minds! If you've ever held a smartphone, driven a car, or even used a simple door hinge, you've interacted with the amazing world of mechanical manufacturing.

It’s the behind-the-scenes magic that turns ideas into tangible, functional things.

But what does that process actually look like? If you picture a sweaty blacksmith with a hammer, you're only seeing a tiny part of the picture! Today, let's demystify some of the core methods engineers use to make the parts that make our world work.

First off, let’s break down what CNC machining actually is. CNC stands for "Computer Numerical Control." It’s a process where machines are controlled by computer programs to precisely cut, shape, or finish materials like metal, plastic, or wood. Think of it as a super-smart robot that's programmed to make super-precise parts over and over again, with minimal human intervention.

It's not just about low costs. China built its manufacturing dominance through:

Complete Ecosystem: In places like Shenzhen and Dongguan, you're within miles of every supplier you could need - from raw materials to precision tools

Massive Skill Pool: Generations of machinists who've trained on everything from basic mills to 5-axis CNC systems

Government Investment: Billions poured into industrial parks and technology infrastructure

Adaptability: Chinese shops will take on projects others would decline

CNC machining in China is used in almost every industry you can think of. Here are a few:

● Aerospace: CNC machining is crucial in the aerospace industry, where parts need to meet strict quality and performance standards. China’s CNC machining capabilities are increasingly being tapped by global aerospace companies.

● Automotive: From engine components to intricate interior parts, CNC machining is used to produce a wide variety of parts for the automotive industry. China is one of the largest manufacturers of automotive parts in the world, and CNC machining is at the heart of it.

● Electronics: Precision CNC machining is key in creating parts for smartphones, computers, and other electronics. The tight tolerances required in the electronics industry make China an ideal destination for sourcing these parts.

● Medical Devices: CNC machines are used to create highly precise parts for medical devices, where reliability and precision are paramount.

Remember when "Made in China" meant poor quality? That's ancient history. Today:

✅ Top-tier equipment: Many shops use German and Japanese CNC machines (DMG Mori, Mazak, etc.)

✅ Stringent QC: ISO 9001 certifications are standard, with many shops meeting aerospace (AS9100) and medical (ISO 13485) standards

✅ Materials matter: They work with the same materials as Western shops - 6061 aluminum, 304 stainless, titanium, PEEK

✅ Precision capabilities: Tolerances of ±0.01mm are routine for quality-focused shops

Looking ahead, China’s CNC machining industry shows no signs of slowing down. With continued investment in technology, better training programs, and improvements in automation, China is poised to remain at the forefront of precision manufacturing for years to come.

Additionally, the global shift toward green manufacturing and sustainability may lead to innovations in how CNC machining is done, and China is likely to be a leader in adopting more eco-friendly practices.

CNC machining in China offers incredible advantages in terms of cost, speed, and precision. Whether you're a startup looking for affordable prototyping or a large corporation in need of mass production, China remains a key player in the global CNC machining market. With advanced technology, a skilled workforce, and strong supply chain integration, China continues to be the go-to destination for companies looking to stay competitive in a fast-evolving market.

We are proud to hold several production certificates for our CNC machining services,which demonstrates our commitment to quality and customer satisfaction.

1、ISO13485:MEDICAL DEVICES QUALITYMANAGEMENT SYSTEM CERTIFICATE

2、ISO9001:QUALITY MANAGEMENT SYSTEMCERTIFICATE

3、IATF16949、AS9100、SGS、CE、CQC、RoHS

● Great CNCmachining impressive laser engraving best Ive everseensofar Good quaity overall,and allthe pieces were packed carefully.

● Excelente me slento contento me sorprendio la calidad deias plezas un gran trabajo This company does a really nice job on quality.

● If there is an issue they are quick to fix itVery good communication and fast responise times

This company always does what I ask.

● They even find any errors that we may have made.

● We have been dealing with this company for a number of years and have always recelved exemplary service.

● I am very pleased with the outstanding quality or mynew parts.The pnce is very competiive and the custo mer service is among the best Ive ever experienced.

● Fast tumaround rabulous quality,and some of the best customer service anywhere on Earth.