CNC Corrosion-Resistant Engine Parts for Marine Vessels & Submarines

When it comes to marine and submarine applications, corrosion resistance isn’t just a feature—it’s a necessity. Harsh saltwater environments demand precision-engineered components that withstand relentless wear while maintaining peak performance. At PFT, we specialize in manufacturing CNC corrosion-resistant engine parts that meet the rigorous demands of marine engineering. Here’s why global clients trust us as their go-to supplier.

1. Advanced Manufacturing: Where Technology Meets Expertise

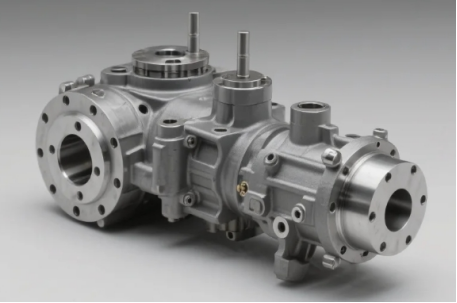

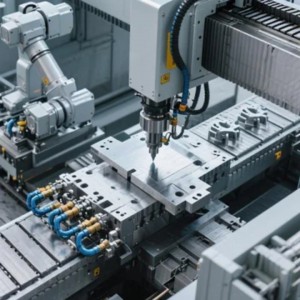

Our factory is equipped with state-of-the-art CNC machining centers and 5-axis milling systems, enabling us to produce complex geometries with micron-level precision. Whether it’s propeller shafts, valve housings, or turbine components, our machinery ensures flawless dimensional accuracy tailored for marine vessels and submarines .

But technology alone isn’t enough. Our engineers bring 20+ years of experience in marine engineering, combining CAD/CAM simulations with hands-on expertise to optimize designs for corrosion resistance and durability.

2. Material Mastery: Built to Last in Saltwater Environments

We use marine-grade materials like duplex stainless steel, titanium alloys, and nickel-aluminum bronze—all rigorously tested for:

- Salt spray resistance (ASTM B117 standards)

- Stress corrosion cracking tolerance

- Long-term stability in high-pressure conditions .

Unlike generic suppliers, we customize material blends to match specific operational environments, ensuring parts perform flawlessly whether submerged at 500 meters or exposed to tropical climates.

3. Quality Control: Zero Compromise on Reliability

Every component undergoes a 7-step quality assurance process:

l Raw material certification (ISO 9001)

l In-process dimensional checks

l Post-machining surface roughness analysis

l Hydrostatic pressure testing

l Salt fog chamber evaluation (1,000+ hours)

l Non-destructive testing (X-ray/ultrasonic)

l Final performance validation .

Our closed-loop quality system guarantees that only parts meeting DNV-GL, ABS, and Lloyd’s Register certifications leave our facility.

4. End-to-End Solutions: From Prototyping to After-Sales Support

We cater to diverse needs:

- Low-volume prototyping for R&D teams

- High-volume production with 30-day lead times

- Reverse engineering for legacy systems

- 24/7 technical support and spare parts supply .

Case in point: Last year, we delivered 120+ custom stern tube bearings for a submarine fleet, reducing downtime by 40% through precision-fit components.

FAQs

Q: How do you ensure corrosion resistance?

A: We apply post-machining treatments like electropolishing and ceramic coatings, proven to reduce corrosion rates by 70% in lab tests.

Q: Can you handle urgent orders?

A: Yes—our flexible production lines support expedited services without compromising quality.

Why Choose Us?

- ✅ 20+ years in marine component manufacturing

- ✅ 98% on-time delivery rate

- ✅ Lifetime technical support

Ready to upgrade your marine systems? Contact PFT today for a quote tailored to your needs.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.