Capacitive Sensor Supplier: How to Choose High-Precision Sensors for Industrial Applications

Are you searching for a reliable capacitive sensor supplier for your industrial automation or automotive projects? Choosing the right supplier can make a huge difference in performance, durability, and cost. In this article, we’ll guide you step by step, based on real-world experience, to help you make the best decision.

Why Choosing the Right Capacitive Sensor Supplier Matters

Not all capacitive sensors are created equal. Working with a trusted supplier ensures:

-

High Precision: Accurate measurements in harsh environments.

-

Fast Response: Sensors that react instantly to touch or proximity.

-

Customization Options: Tailored solutions for specific applications.

-

Long-Term Reliability: Minimal maintenance and long service life.

Example: Our factory recently supplied capacitive sensors for a robotics project, where standard sensors failed to detect subtle movements. Custom high-precision sensors solved the issue, improving efficiency by 18%.

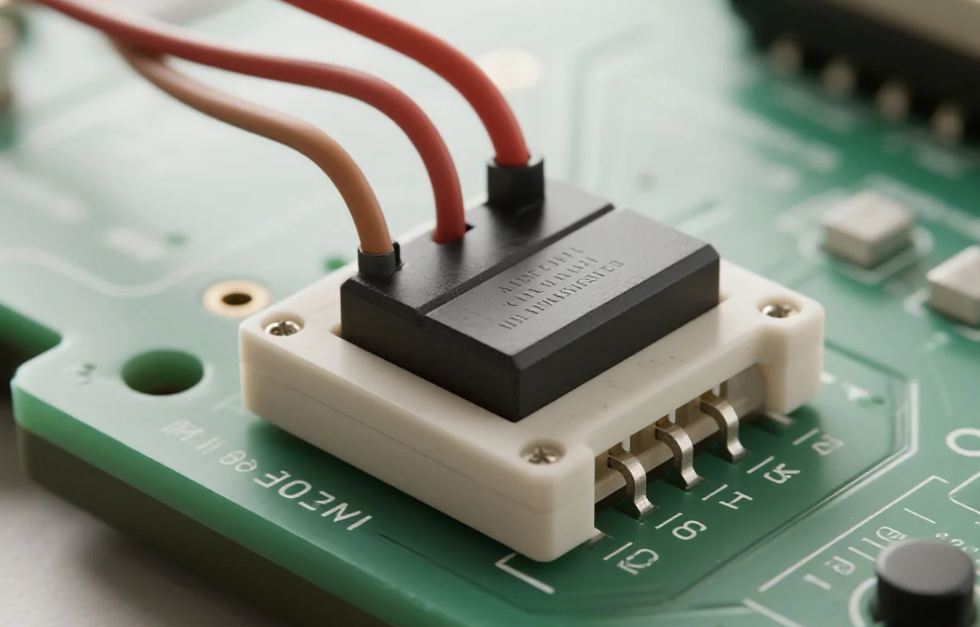

Types of Capacitive Sensors

1. Touch Sensors

Ideal for human-machine interfaces, touch panels, and consumer electronics.

2. Proximity Sensors

Detect objects without physical contact, widely used in industrial automation.

3. Custom Sensors

Tailored designs for robotics, automotive, and medical devices.

Tip: Ask suppliers for datasheets and sample testing. Real-world testing ensures reliability under specific conditions.

How to Evaluate a Capacitive Sensor Supplier

Here’s a practical checklist based on our experience:

| Criteria | What to Look For |

|---|---|

| Product Quality | ISO-certified, consistent accuracy |

| Customization Capability | Ability to modify size, material, or sensitivity |

| Delivery & Support | Lead time, technical support, after-sales service |

| Industry Experience | Case studies or references from similar projects |

| Documentation | Datasheets, installation guides, compliance certificates |

Pro Tip: A supplier providing detailed datasheets and application notes usually indicates strong technical expertise.

Applications of Capacitive Sensors

-

Industrial Automation: Detecting objects on conveyor belts or robotic arms.

-

Automotive: Proximity detection, touch buttons, and parking sensors.

-

Medical Devices: Non-contact sensing for sterile environments.

-

Consumer Electronics: Touchscreens, buttons, and gesture recognition.

Case Study: In one automotive project, our capacitive sensors replaced mechanical switches, reducing failure rate by 25% and improving user interface response.

Tips for Sourcing the Best Supplier

-

Verify certifications: ISO9001, CE, or relevant industry standards.

-

Request samples for testing under real conditions.

-

Evaluate the supplier’s ability to scale production.

-

Compare multiple suppliers using long-tail keywords in your search, e.g.,

high-precision capacitive sensor supplier,custom capacitive sensors for robotics.

Conclusion

Finding the right capacitive sensor supplier is more than just price comparison. Focus on precision, reliability, customization, and real-world performance. By following this guide and leveraging real case examples, you can select a supplier that ensures your project succeeds.

Application

FAQ

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.