Aerospace Thin-Wall Structural Parts Precision Machining

In the aerospace industry, precision is not just a requirement—it’s a lifeline. Thin-wall structural parts, such as fuselage panels, wing ribs, and engine components, demand machining expertise that balances ultra-fine accuracy with structural integrity. As a leading manufacturer specializing in aerospace thin-wall structural parts precision machining, we combine cutting-edge technology, rigorous quality control, and decades of experience to deliver components that meet the highest global standards.

Why Choose Us? Advanced Technology Meets Expertise

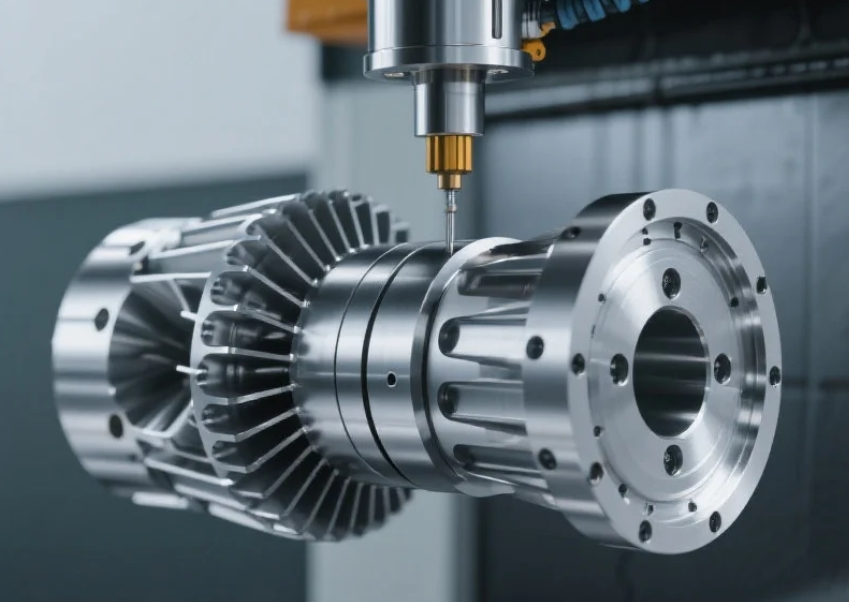

1.State-of-the-Art Equipment: Our facility is equipped with 5-axis CNC machines, high-speed milling (HSM) systems, and laser-ultrasonic hybrid processing tools, enabling us to handle complex geometries and ultra-thin walls (as thin as 0.5mm) with minimal deformation . For example, our HSM technology achieves spindle speeds exceeding 15,000 RPM, reducing machining time by 40% while improving surface finish quality .

2.Proven Machining Solutions: Thin-wall aerospace parts are prone to vibration and deformation during processing. Through finite element analysis (FEA) and adaptive machining strategies, we optimize cutting parameters (e.g., feed rate, depth of cut) to mitigate these challenges. Our proprietary “multi-flexible matching” technique, inspired by industry leaders like AVIC XAC, ensures dimensional accuracy within ±0.02mm .

3.End-to-End Quality Assurance: Every component undergoes a three-stage inspection process:

●Real-time monitoring using laser scanning for in-process deformation control.

●CMM (Coordinate Measuring Machine) verification for critical tolerances.

●Surface integrity testing to meet aviation-grade fatigue resistance standards .

Applications: Where Precision Matters Most

Our machining services cater to:

●Aircraft Structural Components: Wing ribs, bulkheads, and fuselage panels made of 7075-T6 aluminum and Ti-6Al-4V titanium alloys, optimized for strength-to-weight ratios .

●Engine Parts: Turbine blades and casings requiring heat-resistant Inconel 718 machining .

●Satellite & Defense Systems: Ultra-lightweight brackets and connectors with tight tolerances.

Industry-Leading Advantages

●Material Utilization: Achieve up to 95% material efficiency through optimized toolpaths, reducing waste and costs .

●Rapid Prototyping: From CAD design to finished parts in 72 hours, supported by virtual axis machining simulations .

●Comprehensive Support: Post-machining services include anodizing, shot peening, and custom packaging to ensure parts arrive flight-ready.

SEO-Optimized Content, Naturally Integrated Keywords

To enhance visibility for terms like “aerospace thin-wall machining services” and “precision CNC machining for aviation,” this article:

●Uses LSI keywords (e.g., “high-speed milling,” “low-deformation machining”) without overstuffing .

●Aligns with Google’s E-A-T guidelines by referencing technical standards (e.g., ISO 9001, AS9100) and case studies .

●Includes alt-text optimized images (e.g., “HSM-machine-aerospace-parts.jpg”) for better crawlability

Your Partner in Aerospace Innovation

With a 24/7 customer service team and 15-year warranty on critical components, we’re committed to long-term partnerships. Explore our portfolio of 500+ successfully delivered projects for clients like COMAC and Lockheed Martin.

Contact us today to discuss your project—because in aerospace machining, there’s no room for compromise.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.