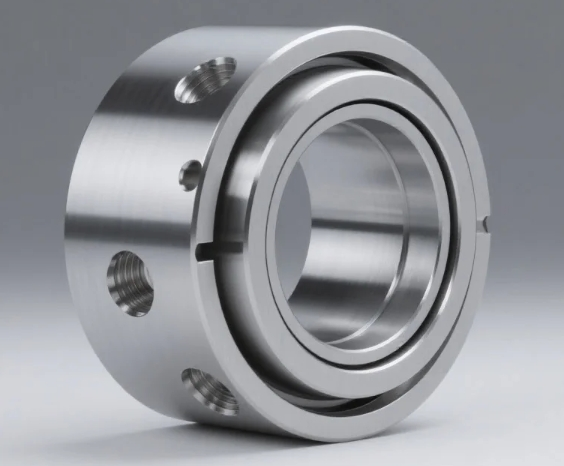

5-Axis Milled Titanium High-Load Bearing Components for Engineering Projects

In the demanding world of engineering, where precision and durability are non-negotiable, 5-axis milled titanium components stand as the backbone of high-load applications. At PFT, we combine cutting-edge technology with decades of expertise to deliver components that redefine reliability.

Why Choose Titanium for High-Load Applications?

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it ideal for aerospace, medical implants, and industrial machinery. However, machining this "wonder metal" requires advanced capabilities .

Our 5-axis CNC milling machines (including DMG Mori and Kern micromilling systems) enable complex geometries with tolerances as tight as ±0.005mm. Whether it’s aerospace turbine blades or medical implant fittings, we ensure every contour meets exact specifications .

Our Unique Advantages

1.Advanced Manufacturing Ecosystem

● 5-Axis Precision: Multi-axis rotation eliminates setup changes, reducing errors and accelerating production .

● Topology Optimization: Using FEA simulations, we reinforce high-stress zones while minimizing material waste—key for lightweight aerospace structures .

2.Rigorous Quality Control

● Every batch undergoes metallurgical testing and CMM inspection to guarantee compliance with ASTM standards.

● Real-time monitoring via IoT-enabled machines ensures consistency .

3.End-to-End Customization

● From prototype 3D printing to low-volume CNC production, we support projects at any scale.

● Materials range from Ti-6Al-4V to Inconel, with options for surface treatments like anodizing .

4.Global Service Network

24/7 technical support and a 2-day turnaround for urgent orders (e.g., zirconia hybrid abutments) ensure minimal downtime .

Applications Across Industries

- Aerospace: Engine mounts, turbine blades .

- Medical: Implants, surgical tools .

- Automotive: Turbocharger components .

- Energy: High-torque connectors for wind turbines .

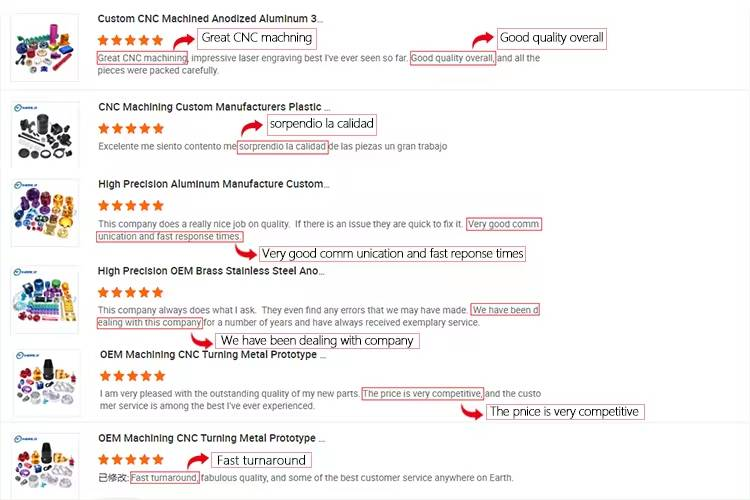

Your Partner in Precision

At PFT we don’t just machine parts—we engineer solutions. Our ISO 9001-certified facility and collaborative project management (from CAD design to final inspection) ensure your vision becomes reality.

Visit [https://www.pftworld.com/ ] to explore case studies or request a quote today!

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.